Engineer-to-Order (ETO)

Bluestar PLM offers a scalable module-based PLM solution for Microsoft Dynamics 365 Finance & Supply Chain Management, delivering different levels of integration with CAD, PLM and ERP, fitting your unique business needs. Start simple by CAD/PDM + ERP Connectors, explore a single business system by having CAD + PLM + ERP with Bluestar PLM, or move your business towards enterprise product configuration by choosing the Product Configuration Module.

Dealing with more complex products and more frequent changes throughout the development phase elongates the time it takes to finalize products and increases the number of specialists involved in a single product’s lifecycle, hence the costs per product. Furthermore, when some of the ever-changing customer requests are missed due to misplacement, engineers are enforced to make corrections in a short period of time. To counterbalance the higher expenses, while keeping the end product’s price at a reasonable level, ETO manufacturers must aim to optimize their internal processes and streamline the product data flow.

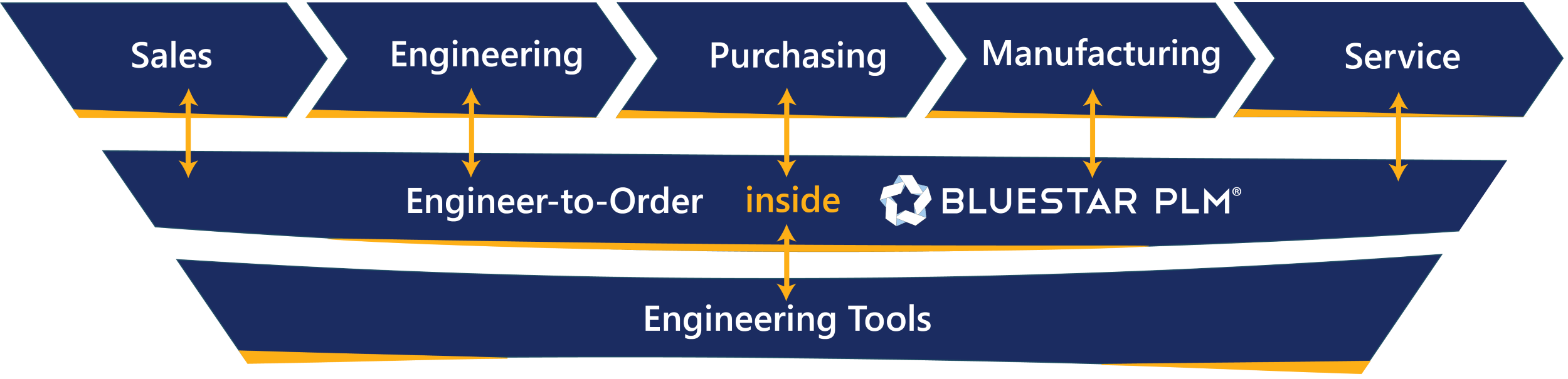

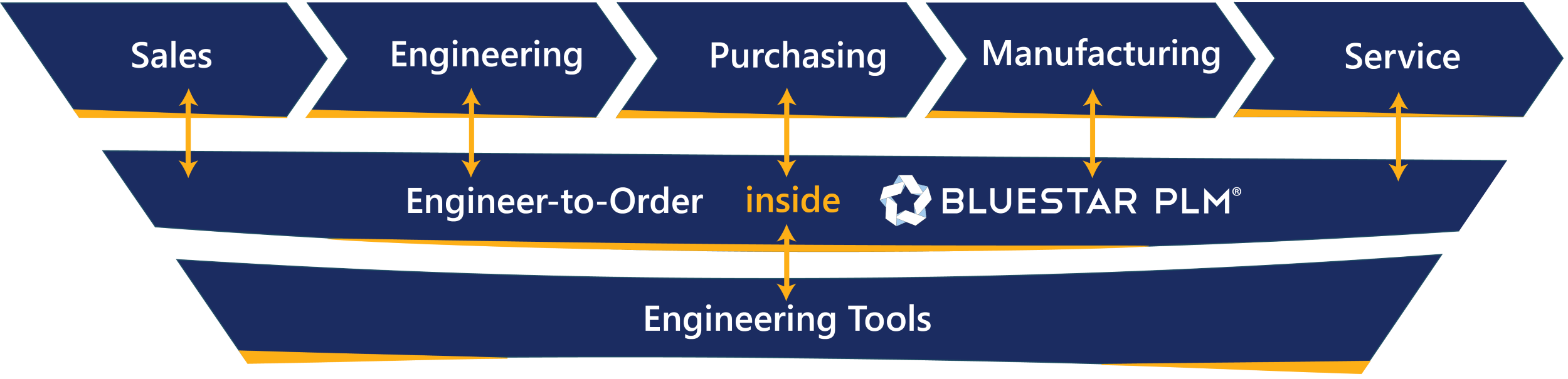

Bluestar PLM allows ETO manufacturers to manage their entire business within one single cloud-based solution, by embedding CAD, PLM and ERP functionality in Microsoft D365/AX

Bluestar ETO gives you:

- CAD+PLM+ERP in one system: For centralizing products and all related information and processes in one place decreasing time to market.

- Management of growing BOMs: Early release long-lead items for a steady flow of raw materials.

- Project management: Workflow driven processes trace growing projects from design to release in D365/AX.

- Reuse of product data: Easily access existing and approved items and BOMs to streamline the development of new products and avoid costly errors.

- Full CAD-intergration: Save time with automatic synchronization of items, BOMs and 3D files between CAD, PLM and ERP.

- Fully traceable Engineering Change Management (ECM): Engineering changes and their impact on products and the supply chain are visible from notice to implementation.

By streamlining and automating end-to-end business processes, you will react to the changing circumstances of one-off projects, by improving collaboration across your organization during product design, fabrication, and delivery.

Connect Enginering and Operations in D365/AX to meet growing customer requirements.

Bluestar PLM is built specifically for ETO manufacturers

The ability to effectively coordinate and execute a constant flow of engineering changes across engineering and operations is key to success in engineer-to-order manufacturing. The supply chain must be efficient and capable.

- Engineering and operations work in parallel and in close collaboration, to avoid bottlenecks, costly errors and delays.

- Meet changes in customer demand, stay on schedule and adhere to budgets.

Effectively coordinate and execute a paralel work-flow across engineering and operations.

Key Features of Engineer-to-Order Module

Attributes and classification module

Based on DIN4000 (classification methodology/structure), the ability to search and reuse existing data and products is essential in saving time and resources.

BOM-builder

Using this CAD-tool allows the user to easily create a BOM structure from scratch or a configured product using existing components. The user can use the this intuitive tool to reuse existing parts and easily assemble them into a complete BOM structure. The BOM is then automatically generated as a CAD model and transferred into Bluestar PLM.

As-built

A product tree structure revealing every bit of information and documentation related to a product after it has been built.

Compliance

Comply with international regulations on substance thresholds for hazardous materials such as REACH and RoHS so your products can go safely to market.

Copy/replace parts – items and structures

Easily copy and replace existing items and products, eliminating the need to start a product design process from scratch, requiring approvals of new items.

Growing BOMs

BOMs can be partially released early, even though the final design of the product is not yet determined and approved. When both engineering and operations work on the same PLM/ERP platform, you can release and communicate long-lead items as soon as possible for purchasing them early in the project.

Project management

Documents running through approval processes and end-to-end business processes are fully traced. Workflows trace designs going back and forth between customer and engineering, as well as growing product requirements and related documentation. The entire project structure can be released to D365 / AX with all project information accessible and centralized in AX. Project templates save the entire project structure for re-use.

Engineering Change Management

Thanks to its integration with both CAD, PLM and ERP environments, it provides complete transparency in the cost and logistic feasibility of engineering changes while securing that engineering documentation is always up-to-date.

Documentation management

Bluestar PLM centralizes and collects product resources and dependencies like data sheets, documents and video, containing essential parameters and manufacturing information.

Engineering Data Export

Transfer product related files from a BOM structure with centralized data, to an external source of your choice. Smart export allows you to select individual files for export in an easy and controlled manner, providing suppliers with all the information they need to manufacture products and fulfill orders.

CAD integration

Allows a tighter collaboration between the engineering and manufacturing team, with allowing CAD users to access and use valuable PLM and ERP data, and utilize CAD drawings on the PLM and ERP side as auto-generated PDFs.

Automatic CAD Designer

A CAD-addin solution, allowing CAD users to search and re-use existing data. Design your new products efficiently by retrieving parts already in your system. Search for related parts for specified parts of an item, geometric similar items, and classifications & attributes.

Your Benefits with Engineer-to-Order Module

Corporate-wide collaboration

Get your product data and documentation under control

Eliminate redundant data entry by automating the exchange of information and files between CAD, Microsoft Office, PLM, and ERP systems. Improves collaboration across departments and locations.

Reuse data for fewer errors and faster product development.

Easily find historical data to significantly lower time spent on designing new products and components; increase overall data quality, and avoid data duplication.

Enhance responsiveness to changes in customer demand

Have complete visibility of the impact of all engineering changes, both in terms of where-used dependencies but also impact on the design, production, purchasing, and inventories. This facilitates better business decisions and ensures that drawings and related documentation always reflect the latest changes.

Full CAD integration

Avoid re-entering data by automatically transferring information from CAD systems to Bluestar PLM inside D365 ERP. Cuts non-value adding work for CAD engineers by enhancing reusability and automating title block-population, and drawing PDF creation for improved data and drawing integrity.

Early release long-lead items

Early release long-lead items that may otherwise take months to acquire. Gives you a steady flow of raw materials so you will not face an avalanche of items to buy, by the time engineering have approved them. Saves you costly delays that are otherwise devastating to any project.

Automate data gathering for suppliers and customers

Achieve greater consistency in the activities involved in providing products or services to ensure the prevention of recurring defects. Export engineering data to your suppliers in a controlled manner, with all related product documentation automatically collected within Bluestar PLM. Saves you time on manual work and minimize the risk of human error.

CAD, PDM and PLM supported by Bluestar PLM:

SOLIDWORKS PDM

AUTODESK VAULT

INVENTOR

SOLID EDGE

SOLIDWORKS

EPLAN

ORCAD

PADS

ALTIUM

DRAFTSIGHT

CATIA

CREO

TEAMCENTER

WINDCHILL

SIEMENS NX

AUTOCAD

AUTOCAD PLANT

AUTOCAD ELECTRICAL

BIM

REVIT

And more…

Manage your 2D/3D files, PDM and CAD systems with Bluestar PLM

Poul Bak Pedersen

Sales Director EMEA

pbp@bluestarplm.com