Product Variant Management

Bluestar PLM upgrades the workflow between PLM and ERP, offering a fully embedded solution in Microsoft Dynamics 365 Finance & Supply Chain Management (D365 F&SCM). When creating a new product variant, Bluestar PLM uses data from its original sources: ERP, PLM, and CAD, thereby removing the need for copying data across systems. Simply create a new product variant e.g., from an existing product design and Bluestar PLM automatically transfers product data from CAD, ERP and PLM systems to the new variant, e.g. BOM, item data, 3D CAD models, CAD drawings, purchasing data, and manufacturing data.

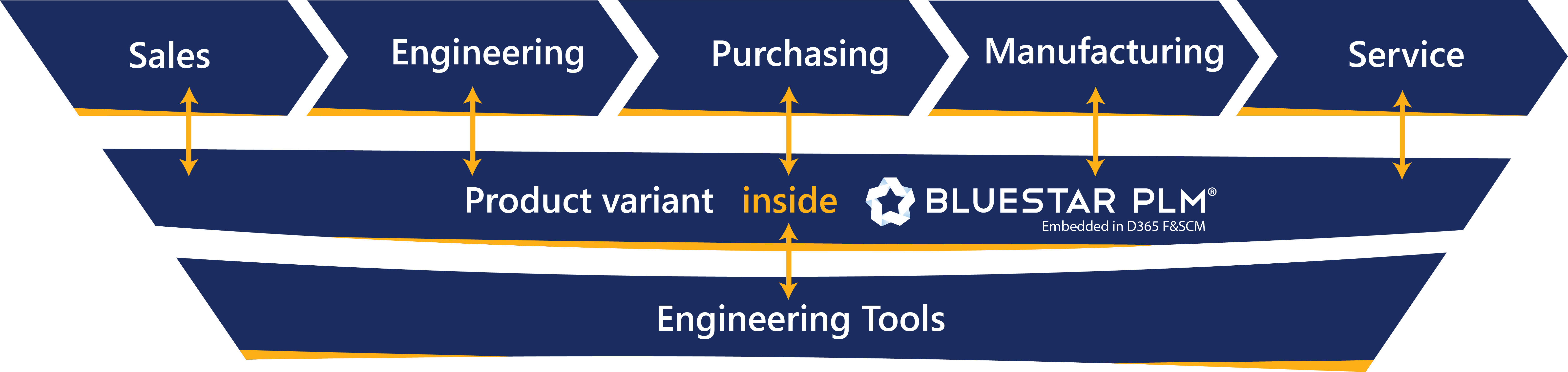

As a key feature, Bluestar PLM minimizes manual data entry for new variants, ensuring a seamless data workflow across the entire value chain; from engineering design and configuration to manufacturing and aftersales service, all of it managed by Bluestar PLM.

Key Benefits

Efficient creation of product variants

With Bluestar PLM, simply create a new product variant from an existing product design. This process automatically transfers product data from CAD, ERP and PLM systems to the new variant, e.g. BOM, item data, 3D CAD models, CAD drawings, purchasing data, and manufacturing data. As a key feature, Bluestar PLM minimizes manual data entry for new variants, ensuring a seamless data workflow managed by Bluestar PLM.

Optimize engineering resources

Bluestar PLM significantly reduces the engineering efforts required across all five approaches to variant creation. Automating validation and control processes frees your engineering team to focus on other critical tasks, maximizing productivity.

Boost reuse potential

Bluestar PLM encourages maximum reuse of existing designs and components regardless of the approach chosen for creating new variants. This strategy not only reduces inventory levels and lead times but also cuts costs and accelerates the delivery of customer requests.

Transparent workflow

Bluestar PLM fosters a transparent and synchronized workflow within Dynamics 365 F&SCM, allowing Operations to monitor the status of (critical) parts in real-time. This visibility means purchasing can begin for components with long lead times as soon as Engineering finalizes the designs, optimizing your supply chain efficiency.

Five approaches to creating product variants with Bluestar PLM

Bluestar PLM supports five dynamic approaches to creating product variants each of them providing different opportunities:

- 1

Copy design of existing product or part: Instantly create a new variant by duplicating the design of an existing product, part, or Bill of Materials (BOM), and then tailor it to fit specific requirements.Your Content Goes Here

- 2

Master BOM configuration (150% BOM): Utilize a comprehensive Master BOM—also known as a 150% BOM or Super BOM—to streamline the management of multiple variants. This approach simplifies the creation process while maintaining full customization options.

- 3

Streamlined product configurator: Empower the variant design process with a product configurator that leverages a predefined solution space. Enforced by rules, constraints or parametric designs, this tool allows for the seamless creation of product variants, ensuring compatibility and coherence across variants.

- 4

Manufacture Lot-Size-One: Extend the product configuration process with autogenerated data for manufacturing, e.g. programs for CNC machines.

- 5

Advanced manual after-configuration: Combine the efficiency of the product configurator with the flexibility of manual customization. Start with the configurator to define the core design and use manual after-configuration for those unique requirements outside the standard solution space.

Key Features

Seamless data inheritance

With Bluestar PLM, tracking variants across all product variants is effortless, enabling quick identification of related products in case of claims or quality issues. This capability drastically cuts down the time spent on backtracking and ensures a robust response to any challenges.

One source of data

With Bluestar PLM embedded in D365 F&SCM, all stakeholders can rely on a single, consistent source of data, significantly reducing the risk of errors and inconsistencies. This data-driven workflow streamlines your operations and enhances product integrity.

Immediate release for Operations

Variants designed within Bluestar PLM’s product configurator are preapproved by Engineering. This streamlines the transition of the product from design to production ensuring a faster response to market demands and customer needs.

What have our customers accomplished?

Automated Bakery Equipment Solutions

Achieved 150% revenue growth, due to PLM and ERP implementation. Errors were reduced, and quality management boosted product reliability and customer satisfaction. Streamlined processes increased productivity across all functions…