Product Configuration (CFG)

Bluestar PLM helps you manage your product configurations and variants stored and controlled in a single business system.

Bluestar Product Configuration helps you:

- Streamline product configuration tasks: With either the Bluestar Product Configurator or D365/AX Product Configurator, you do not have to create the same configurations you use for your products repeatedly. Instead, you can auto-generate a CAD model based on a set of customized and predefined configuration options, saving your engineers time and money on manual and tedious work.

- Create variants from 150% BOMs: From a 150% BOM, you can select from a list of variants for each BOM line which one is active. Based on your selections, you can easily create multiple variant BOMs from the Master BOM. This makes it fast and easy to generate new variants that are synchronized and accessible in CAD and ERP.

- Manage master models and variants in D365/AX: The master model and variants for your products and all related documentation is stored and linked together in one place – D365/AX. This provides your entire business with an easy overview of all products and revisions, with real-time and reliable data, mitigating costly mistakes in production.

- Reuse data to make product development more efficient: Reuse and copy existing and approved product data and all related drawings, BOMs and files, so you will save effort, time and money having to start every new project from scratch.

Reuse product data for seamlessly creating product variants from 150% BOMs in CAD and D365/AX.

See how it works

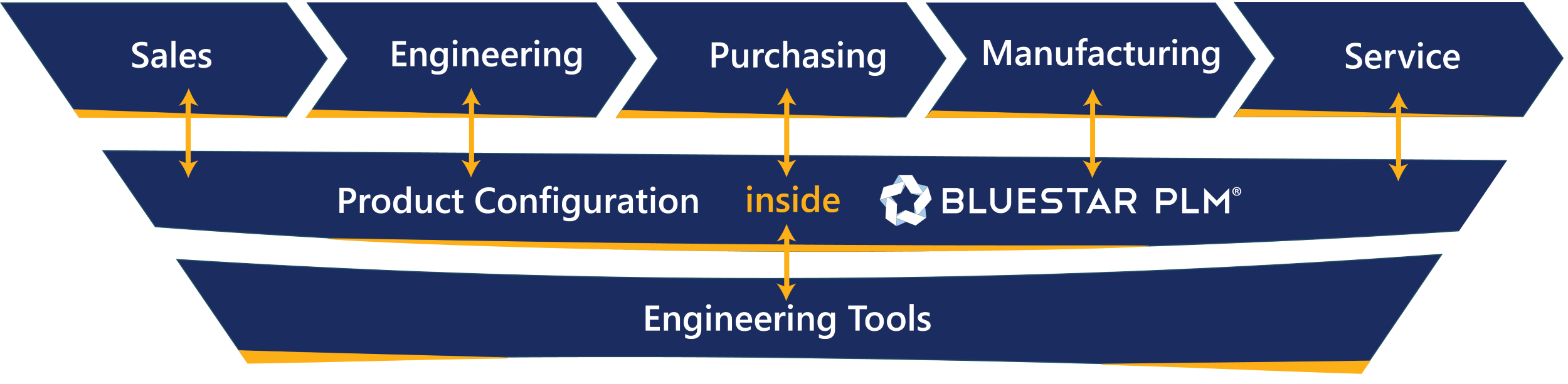

Bluestar PLM provides either the D365/AX-based product configuration platform or our own Bluestar product configurator, which lets you manage the entire configuration process from Quotation through Engineering and Manufacturing in a single system.

- Reduce quote-to-manufacturing time by configuring complex products with full PLM control.

- Automate routine CAD work and prevent engineering bottlenecks.

- Respond faster and more accurately to customers.

- Eradicate double efforts across Sales, Engineering, and Manufacturing.

- Reduce reliance on key product experts.

A single Dynamics-based product configurator for Sales, Engineering and Production.

Key Features of Product Configuration

3D Visualization

Bluestar offers a 3D configuration interface that provides dynamic feedback as you configure. This provides a more intuitive configuration experience to D365/AX users.

Configure Complex Engineered-To-Order Products

Full integration with CAD and PLM platforms enables the controlled, manual processing of complex partially configured products.

CAD Automation

Auto-generate your 3D CAD models and 2D drawings based on the configurations created in the 365F&O/AX configurator (or 365/AX Product Builder) and more complex engineering configuration rules.

Variant management

Manage 150% BOMs including all variants and from that configure 100% BOMs that fits exact customer requirements. Create, manage and maintain product variants and the associated data and documentation to gain an overview of the relations between variants, which designs they originated from and which variants have been created from specific designs.

Dynamics 365 for Finance and Operations & AX Configurator Integration

Leverage the native 365/AX configurator (or the 365/AX Product Builder) or use the Bluestar Product Configurator to generate fast and accurate quotations.

BOM builder

Create an assembly model by mating together and positioning existing items, to build a BOM in a hierarchical structure that can be automatically generated as a CAD model and transferred into ERP.

- Intuitively drag-and-drop items into the BOM structure to adjust item positions and placement.

- Transform the created BOM structure into its 3D CAD model counterpart.

- Build 150% BOMs with a full list of all configuration options to choose from. Automatically insert the selected Master-BOM into CAD.

- Seamlessly check in the BOM structure into ERP for further BOM management and release to production.

Your Benefits with Product Configuration Module

Streamlined Order fulfillment

An integrated and streamlined order fulfillment process from sales order, configuration, quotation, engineering and manufacturing reduces costs per order and increases the number of orders which the company is able to process with an unchanged headcount.

Automate product design to reduce engineering costs

A fast generation of sales documentation (3D models, sales and production drawings, DXF, STEP files and more) and less required involvement by Engineering in the quote process, leads to enhanced responsiveness to customer requests and freed up engineering resources.

A more intuitive approach to product configuration

With 3D feedback to your configuration selections on demand, you experience a far more intuitive approach to product configurations that is easy to use and understand across Engineering, Operations and Sales.

Reduce errors

By reusing parts and items already approved by the engineering team, you can avoid the critical and time-consuming approval phase that new developed parts and items must go through. This reduces errors and saves you time and money.

Minimize trivial engineering tasks

Reduces repetitive work and streamline engineering processes, while engineers can spend less time performing monotonous design tasks in CAD.

Automate tedious, manual design tasks

Automate the process of mating together items and assemblies and turning them into 3D CAD models from 150% to Master BOMs.

CAD, PDM and PLM supported by Bluestar PLM:

SOLIDWORKS PDM

AUTODESK VAULT

INVENTOR

SOLID EDGE

SOLIDWORKS

EPLAN

ORCAD

PADS

ALTIUM

DRAFTSIGHT

CATIA

CREO

TEAMCENTER

WINDCHILL

SIEMENS NX

AUTOCAD

AUTOCAD PLANT

AUTOCAD ELECTRICAL

BIM

REVIT

And more…

Manage your 2D/3D files, PDM and CAD systems with Bluestar PLM

Poul Bak Pedersen

Sales Director EMEA

[email protected]