Medical Devices

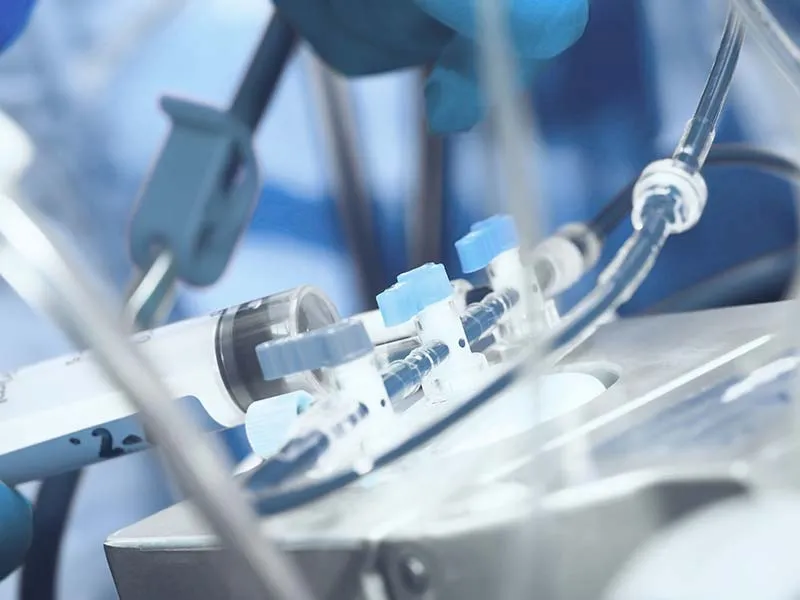

Medical devices manufacturers face a myriad of challenges to successfully deliver innovative and safe products to scaled global markets while complying with quality system regulations. Obstacles include that traditional document management tools fail to manage full product records or complete Bill of Materials (BOM).

Companies having non-integrated systems of data are challenged on several levels. With CAD, PLM and ERP as stand-alone solutions, each with its own data structure, interface and capabilities to fulfill engineering, operations and manufacturing requirements respectively, your employees will bear a burden not compatible with success. To stay competitive, you need to provide a set-up of solutions that interconnect information and processes, not only across the internal enterprise and departments, but to external partners and suppliers as well. Lack of data integrity is fatal to growth.

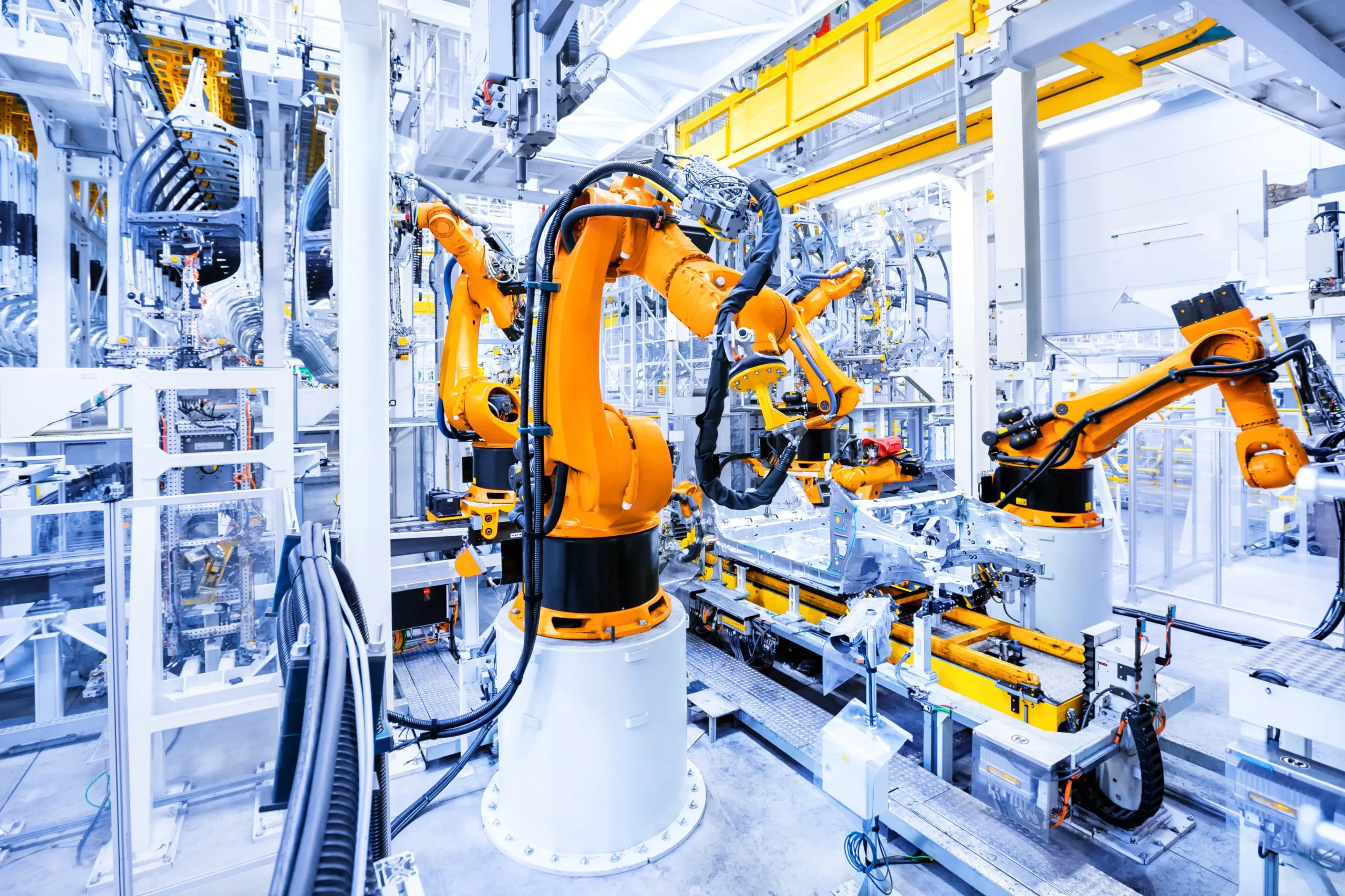

When CAD, PLM and ERP are not fully integrated and operate as silos, corporate-wide information sharing and collaboration becomes nearly impossible. Consequentially, your business suffers delays, miss cost targets, slow change cycles and orders that end up not fulfilling customer requirements. These increased industry demands means that manufacturing companies are facing several critical challenges that are tightly connected to a deep integration between Engineering and Manufacturing.

Challenges of non-embedded PLM and ERP systems

Benefits for Medical Device Manufacturing Companies

Exemption management

Assign approved exemptions to your items, so you will know when allowances permit you to make products that otherwise go against regulations.

Compliance calculation

Bluestar Compliance is capable of automatically calculating the mass and concentration of each substance against the thresholds of specifications. When calculations are easy to perform like this, you reduce the risk of making non-compliant products.

Importing/exporting full material disclosures

Import chemical data and full material disclosure reports into Bluestar Compliance or export them to your suppliers and customers, to ensure all your partners and stakeholders are able to document compliance as they are obliged to. The data is imported automatically in a controlled manner, eliminating the need for manually mapping the data.

Where-used analyses

Reveals all the manufacturing items, exemptions and specifications containing any particular substance. Makes you aware of which products and substances are affected by regulated specifications across your entire product line.

Silicon Expert integration

Seamlessly import and map reliable chemical data on manufacturing items, substances, and specifications from a Silicon Expert, which you need to follow as a compliance obligation. Saves you the effort of doing otherwise error-prone work when manually transferring data from one system to another.

Phase out products End-of-life

Define and manage the last stages of the electrical component’s life, and determine when to stop marketing, selling or reworking for sustaining the product.

Alternative substance names

Any substance can easily be found in the Bluestar system, as you can search for it by both its trivial and a chemical name; i.e. lead = Pb.

Manage manufacturing items

Every manufacturing item gives you a full material disclosure with all chemical data associated with that item. Centralizes all your compliance data in one system for everyone to access.

Revision control

Revise and manage all your manufacturing items and associated data, so you will always know which is the latest version. With revisions, you can also backtrack to find out how and when errors or mistakes happened during engineering change processes.

What have our customers accomplished?

Automated Bakery Equipment Solutions

Achieved 150% revenue growth, due to PLM and ERP implementation. Errors were reduced, and quality management boosted product reliability and customer satisfaction. Streamlined processes increased productivity across all functions…