Microsoft Dynamics 365 PLM Solution

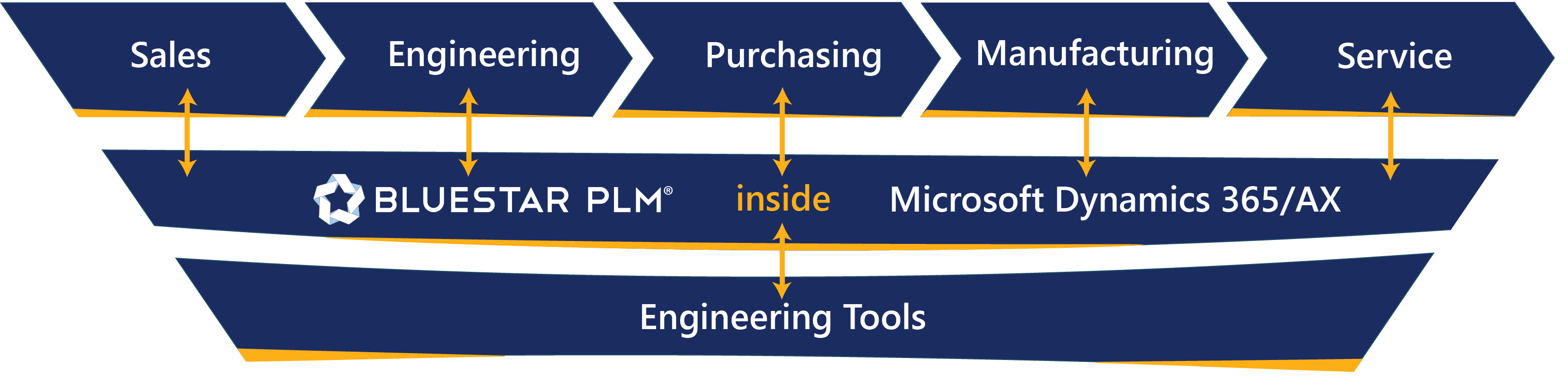

Bluestar PLM offers a scalable module-based Microsoft PLM system which is embedded inside Microsoft Dynamics 365 Finance & Supply Chain Management, delivering different levels of integration with CAD + PLM + ERP, fitting your unique business needs. Bluestar PLM is a single and complete solution that connects the entire enterprise and end-to-end business processes, from early product development all the way to product fabrication and service. This means that you will enable the seamless sharing of data and documentation, and obtain optimal business process automation across Sales, Engineering, Purchasing, Manufacturing, and Service.

Bluestar Dynamics 365 PLM gives you:

- CAD + PLM + ERP data shared in D365 F&SCM: Manage your items, BOMs and 2D/3D-models in one solution.

- One Platform for One Product Truth: Complete data transparency for all departments and locations.

- Engineering Change Management: Transparent ECM that reveals change impact on designs and the supply chain before it is implemented.

- Multi-site Collaboration: Seamless exchange of real-time data in the cloud.

- Workflow Driven Process Automation: End-to-end engineering and operations processes executed in one system.

CAD + PLM + ERP: Digitize your Product Data Highway

One Platform – One Product Truth

Streamlined and transparent data across Engineering, Operations and Manufacturing

- Increase efficiency with Data Reuse and avoid duplicates and eliminate redudant, manual data entry.

- Reduce lead time with One Source of Truth and manage your items, BOMs, 2D/3D-models (mCAD/eCAD) and related product documentation in one solution.

- Decrease errors with Data Flow Management and predict the impact of product changes on product designs, costs and stock across engineering and manufacturing.

Work faster, smarter and global with Bluestar PLM.

Your Benefits with Bluestar PLM system

One Single Source of Product Truth

A seamless flow of real-time information between CAD, PLM and ERP embedded in one system, relieves manual data entry saving you time and money.

Comply with Product Regulations

By storing and managing data on material declarations, chemicals and regulatory specifications in one single solution, you will be able to comply with international substance regulations.

Worldwide Collaboration

Collaborate efficiently across destributed multi-discipline engineering and manufacturing teams, as well as sub-suppliers and the extended enterprise.

Optimal data reuse

By streamlining the reuse of existing product data and files, you will achieve a faster time-to-market, save time and improve product quality.

3D Configuration/Variant Management

Generate 3D Models based on your product configurations, and easily manage product variants. Manage the configuration process in a single system.

Multi-CAD Collaboration

Engineers from all disciplines will be able to easily exchange incremental suggestions for changes throughout the entire development process. This increases multi-domain collaboration.

Optimal data reuse

By streamlining the reuse of existing product data and files, you will achieve a faster time-to-market, save time and improve product quality.

Transparent and Fast Change Cycles

Integrated engineering change management, making the design impact and impact on logistics, manufacturing and cost feasibility of engineering changes fully visible, before they are implemented.

End-to-end Business Process Automation

All your business processes can be fully mapped, monitored and executed from start to finish by bringing together Sales, Engineering, Purchasing, Manufacturing, and Service.

Standard Bluestar Functions

Product

Integration

System

Sharing

Being a part of Microsoft Dynamics 365 modules:

Improved control

Enables the check-in and check-out of office documents for greater control of your product related documentation.

Scailing with D365

Bluestar PLM scales with Dynamics 365 to support the needs of multinational manufactures being the obvious choice as eto solution.

Enterprise-wide collaboration

Collaborate efficiently across destributed multi-discipline engineering and manufacturing teams, as well as sub-suppliers and the extended enterprise.

Optimal data reuse

By streamlining the reuse of existing product data and files, you will achieve a faster time-to-market, save time and improve product quality.

One user interface and a single system to maintain

Leverages the familiar user interface of Microsoft Dynamics 365 F&SCM, with a single system to maintain instead of separate PLM and ERP systems. Having a single interface facilitates user adoption.

Easy installment & maintainment

Being a part of Microsoft Dynamics modules enables Bluestar PLM to be easility installes, modified and maintaned.

Poul Bak Pedersen

Sales Director EMEA

[email protected]