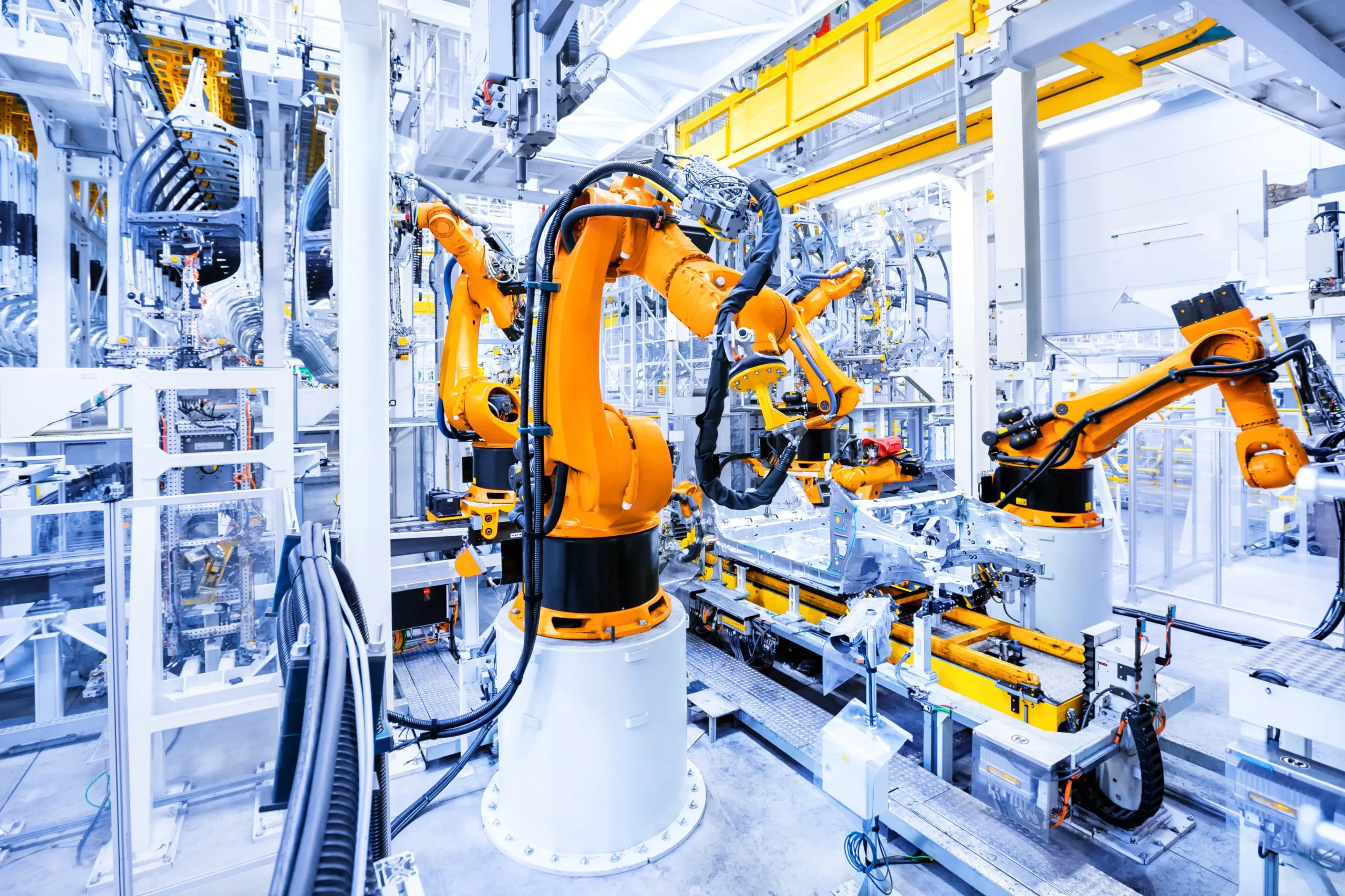

Industrial Manufacturing

Streamline your engineering processes

Industrial Equipment Manufacturers are challenged by the increasing competition within the PLM for manufacturing industry, which, to ensure their position on the market, drives them towards continuous innovations. These innovations aim to create smarter, easy-to-maintain products that fit the often-changing customer needs.

To counterbalance the complex and expensive R&D projects involved in manufacturing PLM, while avoiding the increase in prices or decrease in quality, manufacturers must find a way to optimize their PLM engineering and manufacturing processes. This can be accomplished by cutting non-value adding activities such as redesigning already existing parts, products, and manual data rekeying and transfer between sites, departments, and systems in the realm of PLM manufacturing.

Through the appropriate PLM for manufacturing strategies, manufacturers can streamline their operations, reduce waste, and enhance their ability to adapt to changing market demands. Furthermore, by leveraging PLM engineering solutions, they can better manage product lifecycle, from inception, through engineering design and manufacture, to service and disposal of manufactured products, ultimately fostering an environment of continual improvement and innovation in the PLM manufacturing sector.

Benefits of Bluestar PLM for Industrial Manufacturers

Increase productivity

Streamline the data flow between CAD and ERP through Bluestar PLM, and reduce mistakes while fastening the processes to increase productivity.

Minimize non-value adding activities

Automate engineering processes to abolish non-value adding activities such as manual data rekeying in between systems, generating PDFs out of drawings, and filling out title blocks.

Product visibility

Gain full management over your engineering data with status and revision control. Being embedded in the ERP while having seamless integration to the main CAD systems can allow engineers to access manufacturing data easily and vice versa.

Oversee engineering processes

Enhance multi-site engineering collaboration by using a shared database for engineering data as the single source of truth. Transparency arising from the setup can decrease miscommunication between engineering teams.

Share data easily

Export and share engineering data – including CAD files and documentation – with suppliers and sub-suppliers in a smart and controlled manner.

Utilize existing data

Reuse existing engineering data via classifications and attributes, or machine intelligence-driven CAD-reuse. By this, engineers can focus on core engineering processes, instead of re-creating already existing product designs and data.

What have our customers accomplished?

Automated Bakery Equipment Solutions

Achieved 150% revenue growth, due to PLM and ERP implementation. Errors were reduced, and quality management boosted product reliability and customer satisfaction. Streamlined processes increased productivity across all functions…