Make-to-Stock

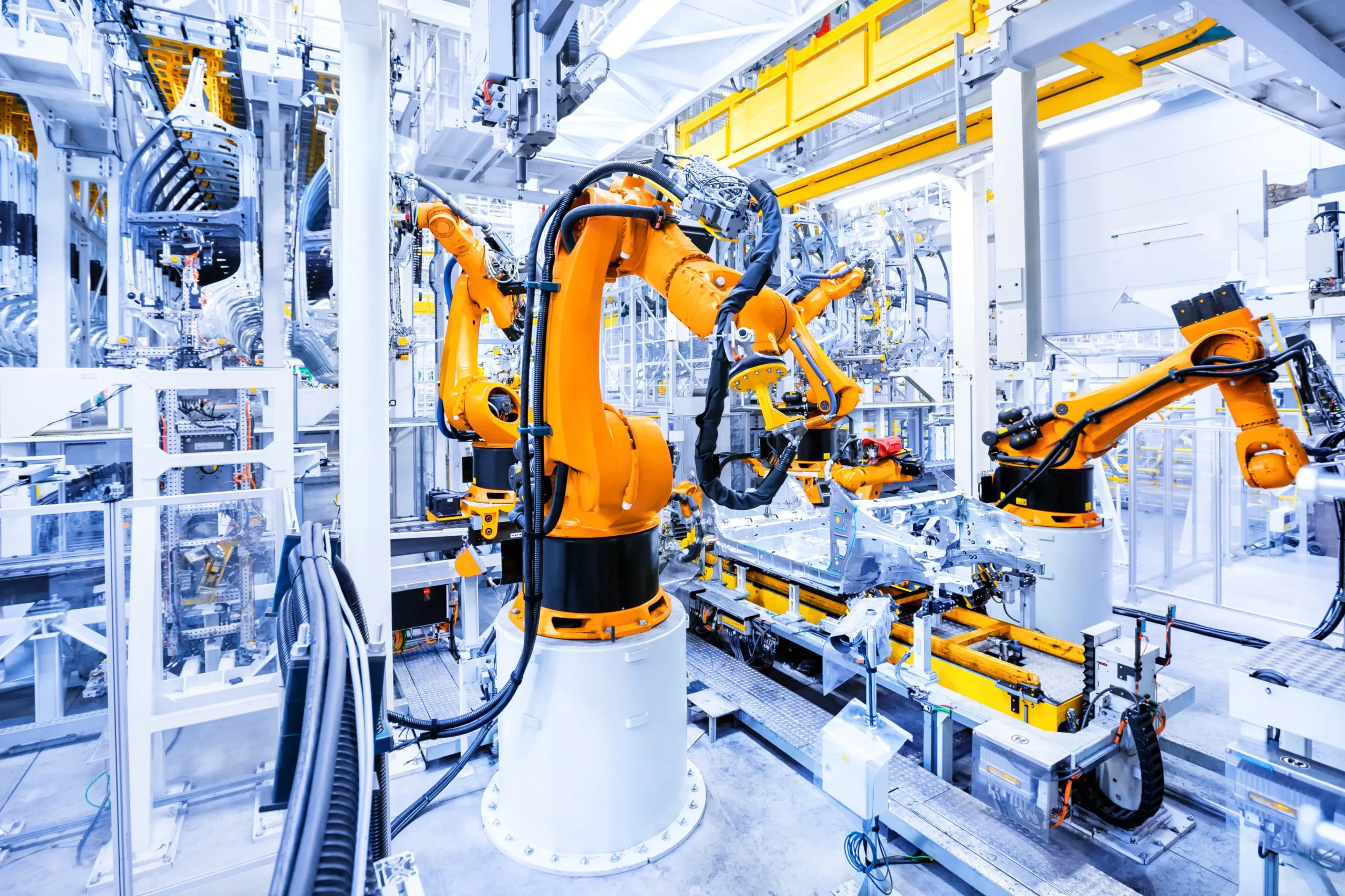

As a make-to-stock manufacturer, Bluestar PLM enhances your operations with a suite of tools designed to improve efficiency and product quality. With an ERP embedded PLM, you can streamline the process of introducing new production, significantly reducing the time to market. Bluestar PLM minimizes regulatory risks by ensuring compliance through improved data management and reporting capabilities. Increased productivity is achieved through enhanced reporting and the automation of repetitive tasks, freeing up your team to focus on more critical aspects of production.

The centralization offered by Bluestar PLM ensures that all departments – from design and engineering to manufacturing and aftersales – work within a single system, fostering collaboration and improving data accuracy. The approach leads to improved quality products as it enhances the synergy between design and manufacturing teams. Automated data sharing within Bluestar PLM ensures that information flows seamlessly across the enterprise, reducing errors and ensuring consistency. This centralization not only improves productivity but also ensures that your make-to-stock operations run smoothly and efficiently.

With Bluestar PLM, Make-to-Stock companies benefit from faster turnaround times for critical processes, such as planning and production scheduling, while maintaining high standards of customization and quality according to customer demands.

Specific benefits for Make-to-Stock Companies

Reduced risk in regulations

With Bluestar PLM, you can automatically calculate if your products substance composures comply with regulations like REACH and RoHS to ensure compliance.

Automated data sharing

Improved time-to-market

By streamlining the reuse of existing product data and files, you will achieve a faster time-to-market, save time and improve product quality.

Improved Quality

What have our customers accomplished?

Automated Bakery Equipment Solutions

Achieved 150% revenue growth, due to PLM and ERP implementation. Errors were reduced, and quality management boosted product reliability and customer satisfaction. Streamlined processes increased productivity across all functions…