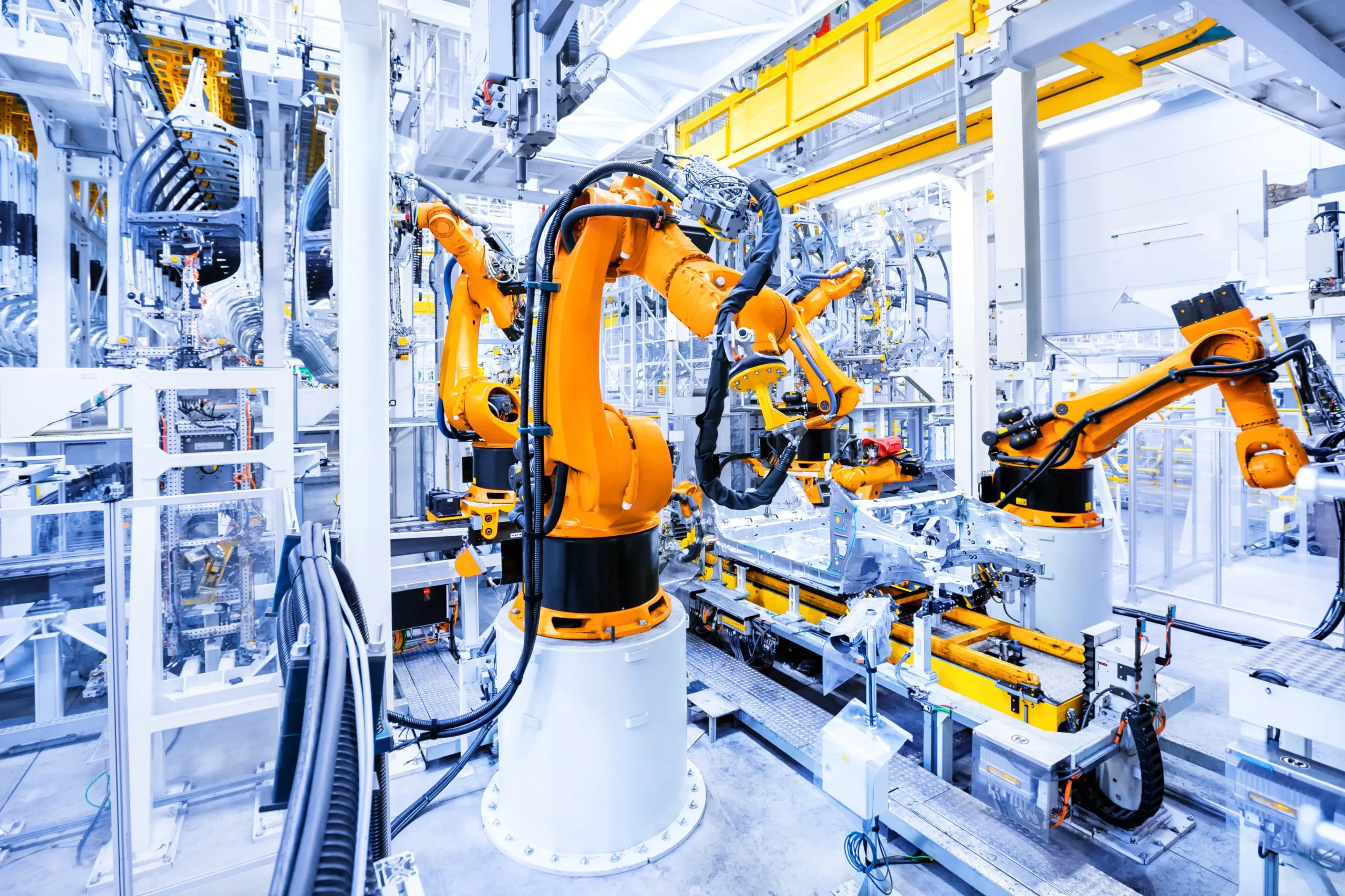

High-tech and Electronics

Todays High-tech and Electronics companies face a reality of increasing product complexity driven by constantly rapid driven technological advances.

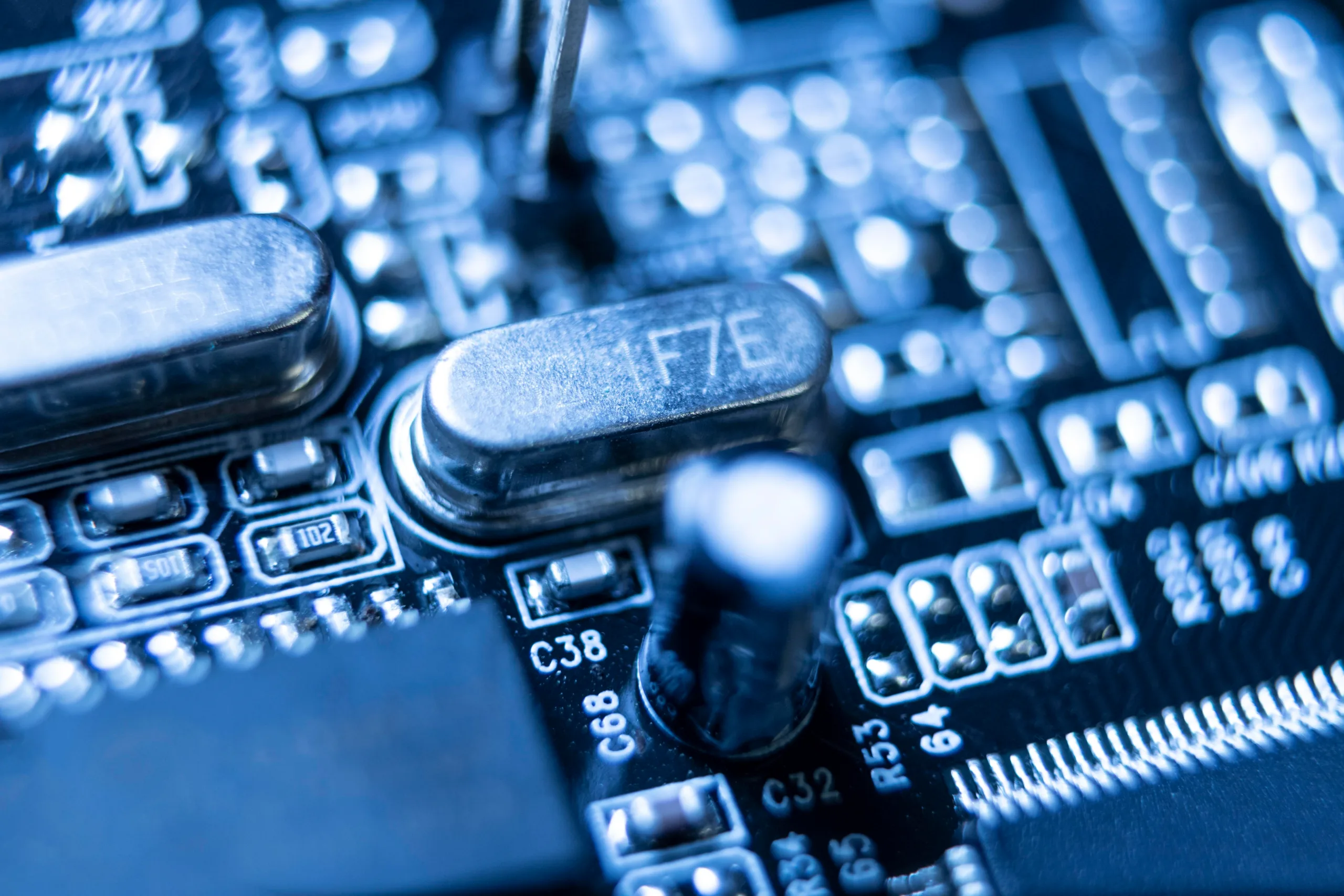

As a manufacturer of electronic products, you need a component management system that provides real-time updates on multiple component sources, so you will acquire only the most cost-beneficial and high-quality parts for your products.

For Electronics companies, Bluestar PLM support a single source of product truth platform that manages component data libraries to ensure data consistency. Bluestar PLM manages new part requests and revisions, part lifecycles and integrate with multiple design tools for improving multi-disciplinary product development and seamlessly sharing ECAD libraries on a global, enterprise-wide level.

It is a solution for your business that helps electronics companies mitigate the risk of experiencing product failures and errors that have a huge impact on product cost, quality, and time-to-market.

Challenges of non-embedded PLM and ERP systems

Benefits for High-tech and Electronics companies

Trace work-in-progress and reduce errors

Track the latest product changes – in real-time – and who made them with audit trails for complete visibility and traceability. In this way, all changes that come in are immediately addressed, to reduce errors and improve efficiency.

Faster product development

Product data (CAD, PLM, and ERP) centralized in a single application promotes greater reuse and saves you time, otherwise wasted on searching for information when all product related data is collected in a single BOM – in a single system.

Improve collaboration between design teams

Integrate multiple formats of mCAD and eCAD design data into one place. Design intent and incremental engineering changes on PCBs and mechanical enclosures are shared immediately between design teams, lowering the risk of discovering constraints and errors late in development. Grants you a faster and more efficient development process.

Seamlessly share parts libraries on an enterprise level

Part information and lifecycle status, as well as lead time information, is acquired prior to releasing the BOM for approval. This vastly improves time-to-market and mitigates the number of errors related to component stock issues or obsolescence.

Uphold your product compliance obligations

Identify non-compliant products before costly mistakes are made at the release of the product into manufacturing. Avoid products being taken off-market, paying huge fines, and suffering severe credibility loss of your brand.

Integrate global business processes

End-to-end issues are tracked and coordinated, and change impact analysis lets you understand the impact of design decisions, for a far more optimal and cost-beneficial design process.

Better quality products

Allows you to standardize your business processes to easily repeat them over and over. This makes it much easier to optimize your predefined product configurations, for optimal end product.

Fewer mistakes

Repetition of processes also means more routine in execution. Potential errors are prevented, and production goes faster.

Shorter time-to-market

With Bluestar PLM fully embedded in Dynamics 365 F&SCM, departments and sites can extend their work and collaborate in a single digital environment, so sales, engineering, procurement, and manufacturing processes can run parallel to each other, eliminating wait times.

What have our customers accomplished?

Automated Bakery Equipment Solutions

Achieved 150% revenue growth, due to PLM and ERP implementation. Errors were reduced, and quality management boosted product reliability and customer satisfaction. Streamlined processes increased productivity across all functions…