Electrical CAD

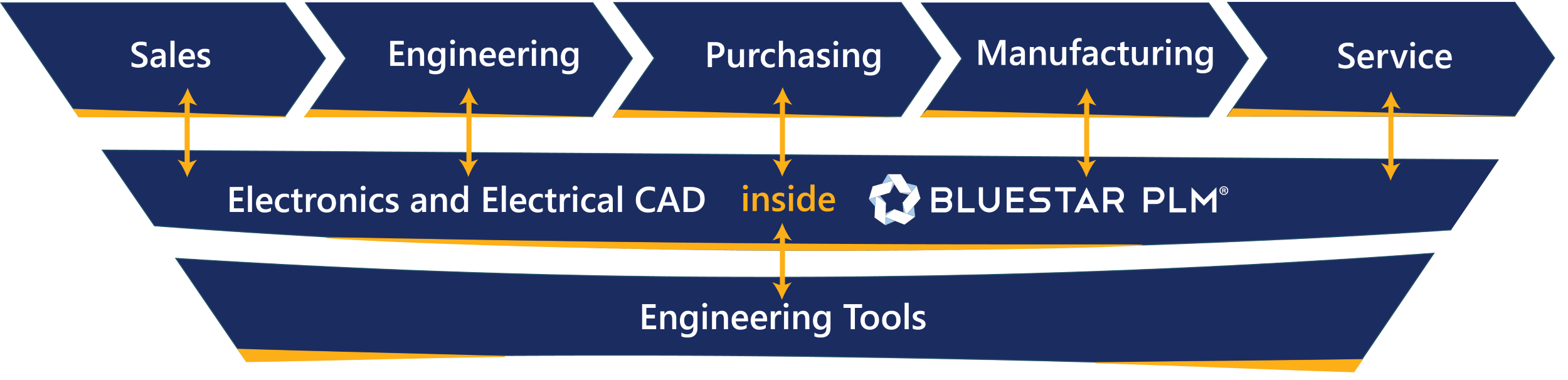

In today’s market in manufacturing, products are more complex than ever, with an increased amount of mechatronic products consisting of both mechanics, electrical components, and software systems. This challenge requires a tight collaboration between engineers from all disciplines, which makes not only the product, but the product development process more complex as well. This complexity generates a lot of both ECAD and MCAD product data, which manufacturers use multiple systems and solutions to manage and maintain.

A lack of integration between these systems and interfaces leads to poor data management, handled through manual, error-prone, and time-consuming processes, leaving a lot of data inconsistency in their wake. Bluestar EPLAN integration allows you to define your products by supporting a BOM containing both electrical and mechanical components existing in a single solution for everyone in the enterprise to share product information, which facilitates the communication across Engineering disciplines and Operations and Manufacturing.

Embedding your electical solution with Bluestar PLM helps you:

- Seamlessly share multi-disciplinary CAD data for optimum efficieny:By automatically synchronizing data bi-directionally between ECAD and Bluestar PLM, you will have your MCAD/ECAD product data centralized in a single structure for each of your products

- Complete design data in D365/AX for faster time-to-market: The syncronization gives your Design teams the ability to share design information and engineering changes in real-time. In turn, the design process become more streamlined, with fewer bottleknecks between domains and a faster time-to-market.

- Complete data visibility for data reuse andfewer manufacturing mistakes: The ability to syncronize your MCAD/ECAD projects , make users versatile, so they won’t have to switch between applications. As a result, your product development process becomes more efficient, saving you time and money.

- Automate processes for fewer errors and less waste: Upon checking out a project from Bluestar PLM, the project is automatically transferred into ECAD system. From here modifactions, are immidiately applied to the project in Bluestar PLM, when chekcing it back in.

- Early release BOMs to avoid delays and limit costs:Bluestar PLM allows you to release a partial BOM, with both ECAD and MCAD design data, so long-lead items can be procured early in a project.

Synchronize component data between ECAD and D365/AX to streamline PCB designing.

Supported CAD systems

Bluestar PLM is fully integrated with multiple mainstream ECAD systems for the design of electronic products:

EPLAN

SUBIN

AUTOCAD ELECTRICAL

MCAD/ECAD data in a single structure for improved collaboration accross the enterprise

- Streamlined Project Oversight in Bluestar PLM: After finishing a project, use Bluestar PLM to view detailed BOM and sub-BOM. It integrates MCAD and ECAD data, ensuring complete connectivity and alignment throughout the design process.

- Reducing Risks with Integrated Data Management: Using Bluestar PLM to combine MCAD and ECAD data reduces errors and inconsistencies, streamlining project execution and lowering correction costs during production and deployment.

Connect Engineering and Operations by integrating CAD with PLM/ERP inside D365/AX.

Your Benefits with Electrical CAD Module

Automatic BOM genereation upon check-in

A BOM for the electrical project is automatically created upon checking the project into Bluestar. The product BOM contains all your MCAD/ECAD data for the product, giving all users access to the complete product from a single touchpoint.

Collaboration across design-domains

By having mechatronic BOM’s in a single solution, users from all Engineering disciplines can communicate design-intent and share synchronized BOM revision for fewer errors and improved product quality.

Reuse already existing data

Modify and reuse existing MCAD/ECAD data, for future projects. Shortens lead time and limits time and money wasted on re-work.

MCAD and ECAD integration

With all your ECAD/MCAD data in one solution, you will avoid spending time and money on manual and error-prone processes connected with re-creating or exchanging data between several applications.

Trace your suppliers to get the most cost-beneficial parts

Bring all your design domains onboard the same platform – D365&AX – for a streamlined and efficient product development process, which exposses issues for fewer costly mistakes late in the design process.

One source of truth for mechatronic product data

Monitor all your workflows, activities, revisions, modifactions and engineering changes connected with MCAD/ECAD product data in a single system, to become more efficient and lessen the management burden.

Poul Bak Pedersen

Sales Director EMEA

[email protected]