10 Reasons to chose an ERP-based PLM over a stand alone product

Imagine a single unified system that not only enhances data reliability and process transparency, but also reduces the IT challenges associated with maintaining and monitoring two separate environments. This system facilitates enhanced information flow, and shortemed lead-times, by seamlessly connecting previously isolated departments such as engineering and manufacturing. The outcome? A significant increase in the overall company efficiency.

Current Challenges in Engineering

and Manufacturing

In today’s manufacturing companies, CAD, PLM and ERP solutions are traditionally implemented as standalone solutions, which each has its own data structure, interface and capabilities to fulfill Engineering, Operations and Manufacturing requirements respectively. However, with the rise of Industry 4.0, for manufacturers to stay competitive they must be able to implement solutions that interconnect information and processes not only across the internal enterprise and departments but external partners and suppliers as well.

When CAD, PLM and ERP are not fully integrated and operate as silos, corporate-wide information sharing and collaboration becomes nearly impossible. Consequentially, manufacturers suffer delays, miss cost targets, slow change cycles and orders that end up not fulfilling customer requirements. These increased industry demands entail that manufacturing companies are facing several critical challenges that are tightly connected to a deep integration between Engineering and Manufacturing.

Non-Value Added Work

Manufacturers are, on average, spending a third of their time on non-value-adding work such as searching for data, manual data entry, and keeping up with minor engineering changes from CAD to ERP. This absorbs often overqualified human resources that should be focused on value-adding activities instead. Consequently, productivity is hampered when engineers work with outdated data and lead times are negatively affected. In addition, data entry errors that occur in the manual re-keying process lead to costly rework and wasted time.

No Visibility in End-to-End Business Processes

Efficient management of business processes remains a major challenge for discrete manufacturers who undertake complex procedures daily. The central issue stems from the coordination and transfer of information, tasks, and documents among a diverse group of individuals from various departments. Attempting to handle such processes manually can be not just an often overwhelming task but also a factor that negatively affects the company’s overall productivity.

The Cost of Decentralized Product Data

Manually attempting to synchronize data across CAD, PLM, and ERP platforms is not only time-consuming but also frequently leads to discrepancies between the data used by Engineering and Manufacturing departments. In many cases, Engineers and Operations teams find themselves relying on outdated information due to lagging communication between engineers and third parties. This issue is exacerbated in engineer-to-order environments where high rates of change escalate the necessity for repetitive manual data re-entry, further compounding the difficulty of maintaining accurate and up-to-date records.

To avoid errors in assembly or fabrication, it is imperative that the manufacturing floor has unimpeded access to the most recent design data.

BOM Update in Silos

Operations teams need to be notified as early as possible when a new Bill of Materials (BOM), or even a segment of it, has been released with forthcoming new requirements for part numbers. Early notification is crucial for the Purchasing department to procure long-lead items at the initial stages of a project.

This proactive approach prevents Operations and Manufacturing from facing a late surge of part releases, a scenario that can result in high costs and extended delivery times. By staying ahead of this, they can avoid the potential release of an avalanche of expensive parts late in the project cycle that take months to be delivered.

Bottlenecks in Order Fulfillment

Often, Sales, Engineering and Operations work in detached IT systems such as product configurations, CAD applications, PLM and ERP systems. This disconnects results in an order fulfillment process characterized by duplicate data entry and the manual exchange of information across Sales, Engineering and Operations.

The result is prolonged order processing, which increases costs per order and limits the number of orders that the organization is able to process within a given time frame with a fixed number of resources available.

Leveraging Product Knowledge

Manufacturers aim to streamline their production processes by re-utilizing existing parts in new products and items. Since these parts have already been tested and approved, reusing them can save valuable time compared to developing new components from scratch. Currently, many design teams undertake the vital yet inefficient task of manually searching for these parts – a process that, despite being trivial, remains essential.

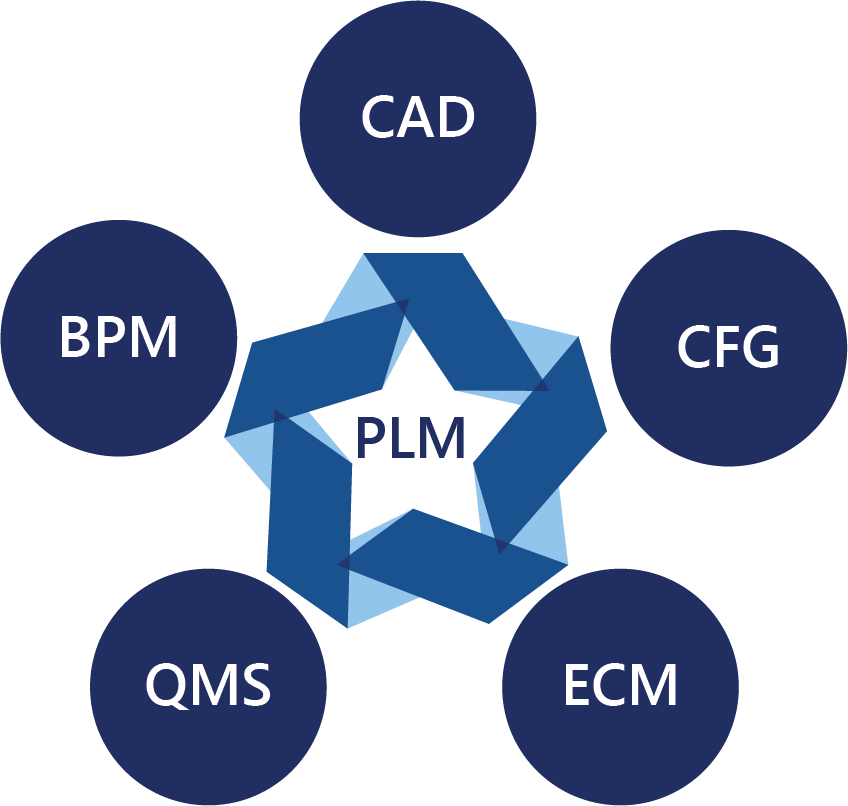

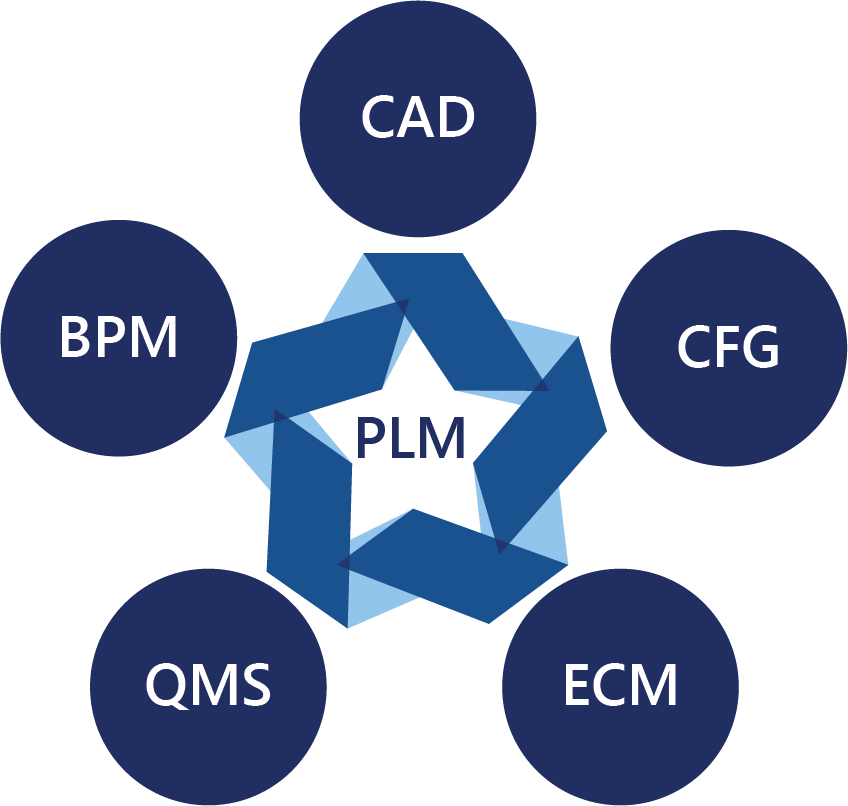

PLM Embedded in Microsoft Dynamics 365 F&SCM

Bluestar is a PLM solution, fully embedded as an add-in module for Dynamics 365 F&SCM. As a modular PLM software, it gives a customizable and scalable solution to support the desired parts of manufacturing, fitting into the areas already covered by Dynamics 365. This means that…