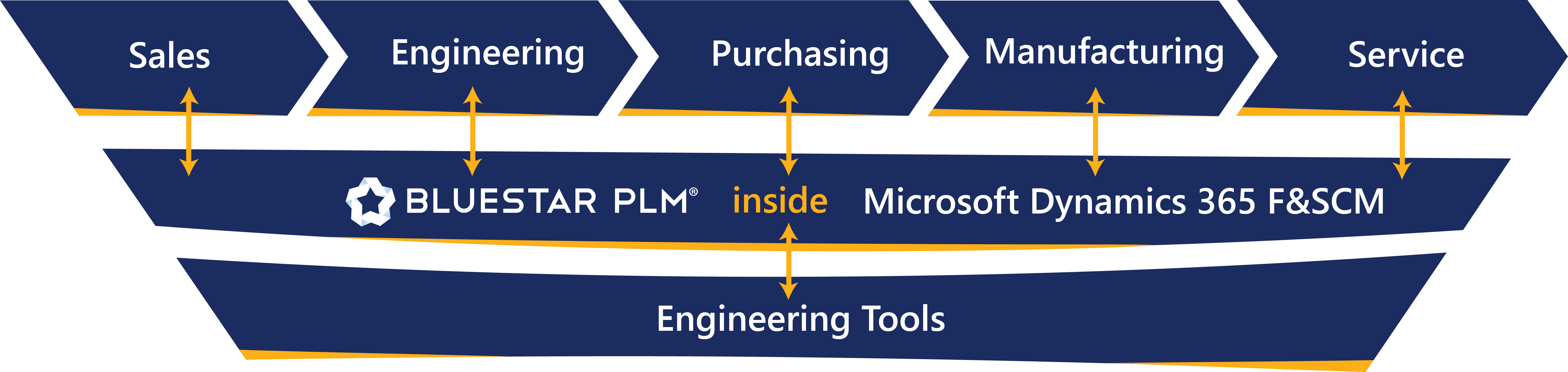

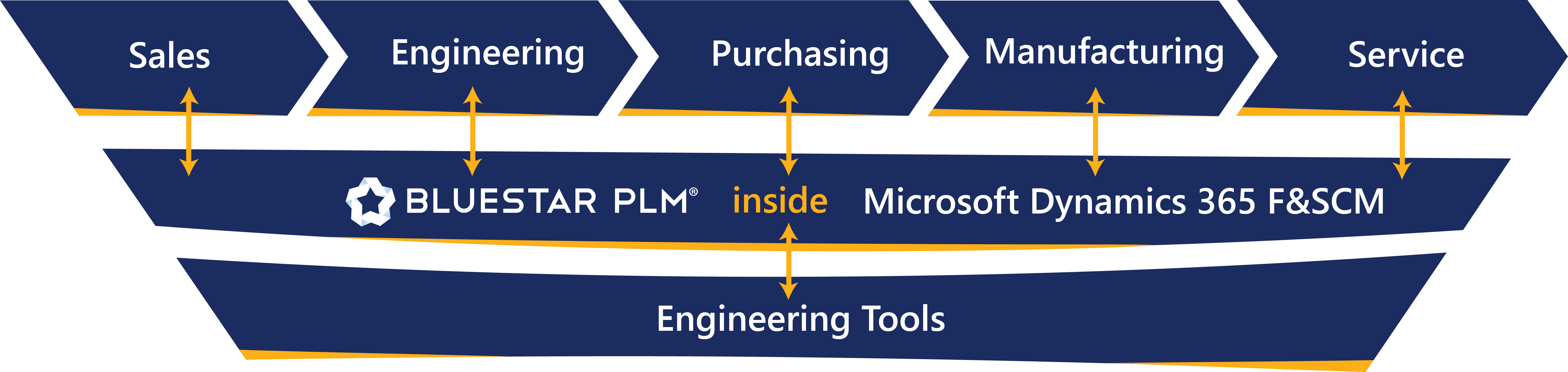

Bring your engineering inside Dynamics 365 F&SCM

CAD + PLM + ERP for seamless data flows across:

Sales, Engineering, Purchasing, Manufacturing and Service

CAD + BLUESTAR PLM + ERP

One Platform – One Product Truth

Synchronize and optimize your product data highway to increase efficiency, reduce lead time, and decrease errors by implementing ERP based PLM.

Reduce lead time with

One Source of Truth

- Product data from CAD + PLM + ERP applications in a single revision-controlled data repository.

- All information is available at point-of-use.

- Complete data transparency for all departments and locations.

- Manage your items, BOMs, 2D/3D-models (mCAD/eCAD) and related product documentation in one solution.

Decrease errors with

Data Flow Management

- End-to-end business process automation.

- Two-way exchange of data between CAD + PLM + ERP.

- Impact of product changes on product designs, costs and stock is fully predictable across engineering and manufacturing.

- Integrated with Microsoft Field Service.

Increase efficiency with

Data Reuse

- Optimize your engineering work by reusing data across CAD + PLM + ERP.

- Avoid duplicates and eliminate redundant, manual data entry.

- Cloud-based worldwide collaboration between subsidiaries and suppliers.

10 Reasons Why You Need ERP based PLM

Learn why PLM – Product Lifecycle Management, is essential for your manufacturing company to enter Industry 4.0 / Manufacturing-X. By having a single solution where the PLM system is embedded in ERP, you can fully leverage product data to satisfy customer demands and deliver orders on time and within budget.

Examples of Customer Achievements with Bluestar PLM

To learn more about how different customers have reached these incredible results, read our Customer Case Stories where you can learn about the background, success criteria and results of different customers, or click below to learn more about the benefits of Bluestar PLM.

What our customers say

We chose Bluestar because it is an engineering solution. It could also integrate with computer-aided design (CAD), something that is extremely important for us as a manufacturer. Ultimately, it just blew the socks off the competitors as an engineering-focused solution to manage our parts, products and lifecycle management.

Stefan Naude, Engineering Director, Bel Power Solutions

We realised that we had a unique opportunity to implement ERP and PLM together to integrate the way we manage all of our product data. We would not get this chance again, and so we looked for a PLM solution that worked inside Dynamics AX. Microsoft independent software vendor Bluestar PLM was the only company that could deliver this capacity.

Phil Wood, Chief Information Officer, Rotork

The way Bluestar PLM interacts with all the other areas of our ERP system makes it very powerful. For example, with Bluestar, it takes about 90 seconds to both configure the part and create the CAD drawing. There is really no comparison when it comes to what you can gain by having software like that.

Farooq Mohammad, Director of IT, Hannibal Industries

ERP based PLM from PDM technology

+20 years of experience in bringing together global engineering & operations teams

PDM technology is the team behind Bluestar PLM. We were founded in the 80s, serving the prime goal to help global manufacturing companies by easy implementable, out-of-the-box solutions developed to leverage data re-use, transparency and work flow. Bluestar PLM was developed as the premiere engineering solution for Dynamics 365/AX to support a seamless integration between engineering data from CAD and to the entire enterprise.