Engineering Bill of Materials (eBOM) and Manufacturing Bill of Materials (mBOM)

Bluestar PLM offers a scalable module-based PLM solution for Microsoft Dynamics 365 F&SCM, delivering different levels of integration with CAD, PLM and ERP, fitting your unique business needs. Start simple by CAD/PDM + ERP Connectors and explore a single business system by having CAD + PLM + ERP with Bluestar PLM.

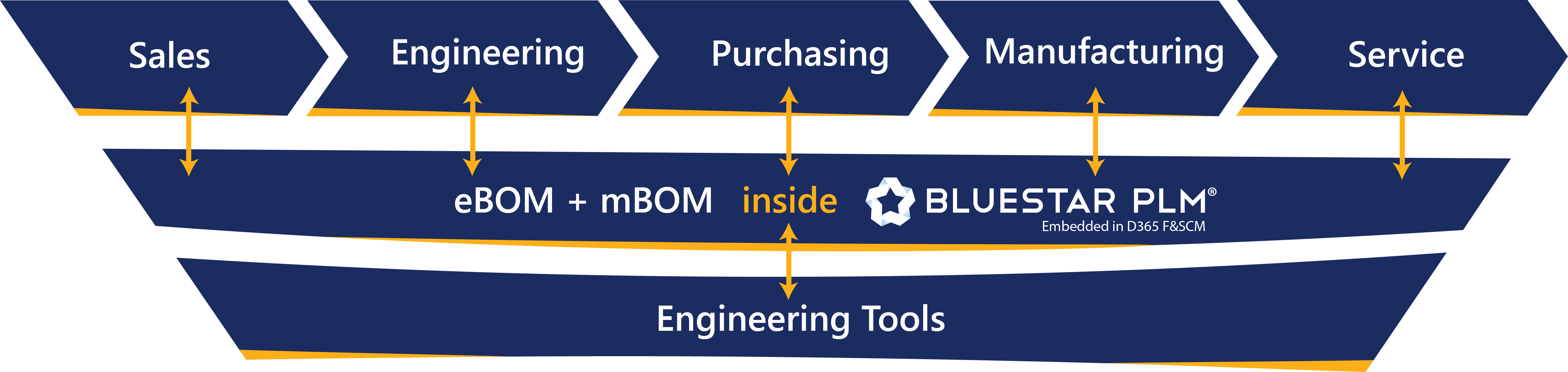

Traditionally, the engineering bill of materials (eBOM) resides within a PLM system, with the manufacturing bill of materials (mBOM) developed and stored in the ERP system. This often necessitates manual data translation, comparison, and updating across platforms, posing a significant risk of inconsistency between the eBOM and mBOM.

Bluestar PLM embedded in Microsoft Dynamics 365 Finance & Supply Chain Management (D365 F&SCM), offers one single solution for smart management of data in both eBOM and mBOM. Our solution ensures that changes to product design affecting the eBOM are automatically aligned with the mBOM providing several features to support building an accurate mBOM.

Bluestar PLM eBOM+mBOM Module gives you:

- Reliable production preparation and planning: The status function in Bluestar PLM ensures that the Manufacturing team is informed about any changes to the eBOM which require the mBOM to be revisited. Ensuring that an outdated mBOM is not used for production preparation and planning.

- Interlinked product variant from CAD model to eBOM to mBOM: All product data from CAD model and drawing to eBOM to mBOM is interlinked with Bluestar PLM. Make a change to the product design and eBOM and this is reflected in the mBOM.

- Lower error rates in mBOM preparation: With the automatic alignment of BOM lines from eBOM to mBOM, human errors occurring from manual entries are eliminated.

- Improved lead time: The eBOM+mBOM module in Bluestar PLM brings the collaboration across Engineering and Manufacturing to a new level, reducing manual tasks in the process of bringing a new product to life improving the lead time from design to manufacturing

Key Features and Benefits of eBOM+mBOM Module

Assisted mBOM preparation

Bluestar PLM simplifies mBOM preparation by aligning initial mBOM structure with eBOM. It allows rearranging levels, adding parts not in eBOM, splitting quantities, and aggregating identical items for efficient manufacturing planning.

Keeping track of eBOM and mBOM consistency

The module tracks entries, highlighting similarities and differences, ensuring data consistency, and improving process transparency.

Revision control

Product design changes, supply issues, or operational challenges often demand eBOM revisions, influenting corresponding mBOM updates for accuracy and consistency, which is streamlined by Bluestar PLM, ensuring consistency and accuracy between the eBOM and mBOM.

Automatic alignment of eBOM+mBOM data

Bluestar PLM automates eBOM and mBOM alignment after Engineering approval, streamlining data entry and enhancing manufacturing details for product development.

Global eBOM, local manufacturing site mBOM

Our system allows you to specify the site and generate a tailored mBOM to meet its specific needs, while remaining linked to the global eBOM. This ensures flexibility while maintaining consistency across sites.

Key Benefits with eBOM+mBOM

One source of data truth

BOM lines in the product’s mBOM are interlinked with the product’s eBOM ensuring that the eBOM and mBOM are always up-to-date.

Boost Engineering & Manufacturing Operations:

Examining service order history reveals all related repair drawings, streamlining collaboration and reducing redundancies, thereby saving time and costs.

Enhance Financial Resources & Project Overview

Integrates with D365 for detailed service project insights, cost analysis, and documentation, including direct and indirect expenses for informed decisions.

Explore our other modules

Poul Bak Pedersen

Sales Director EMEA

[email protected]