Aerospace and Defense

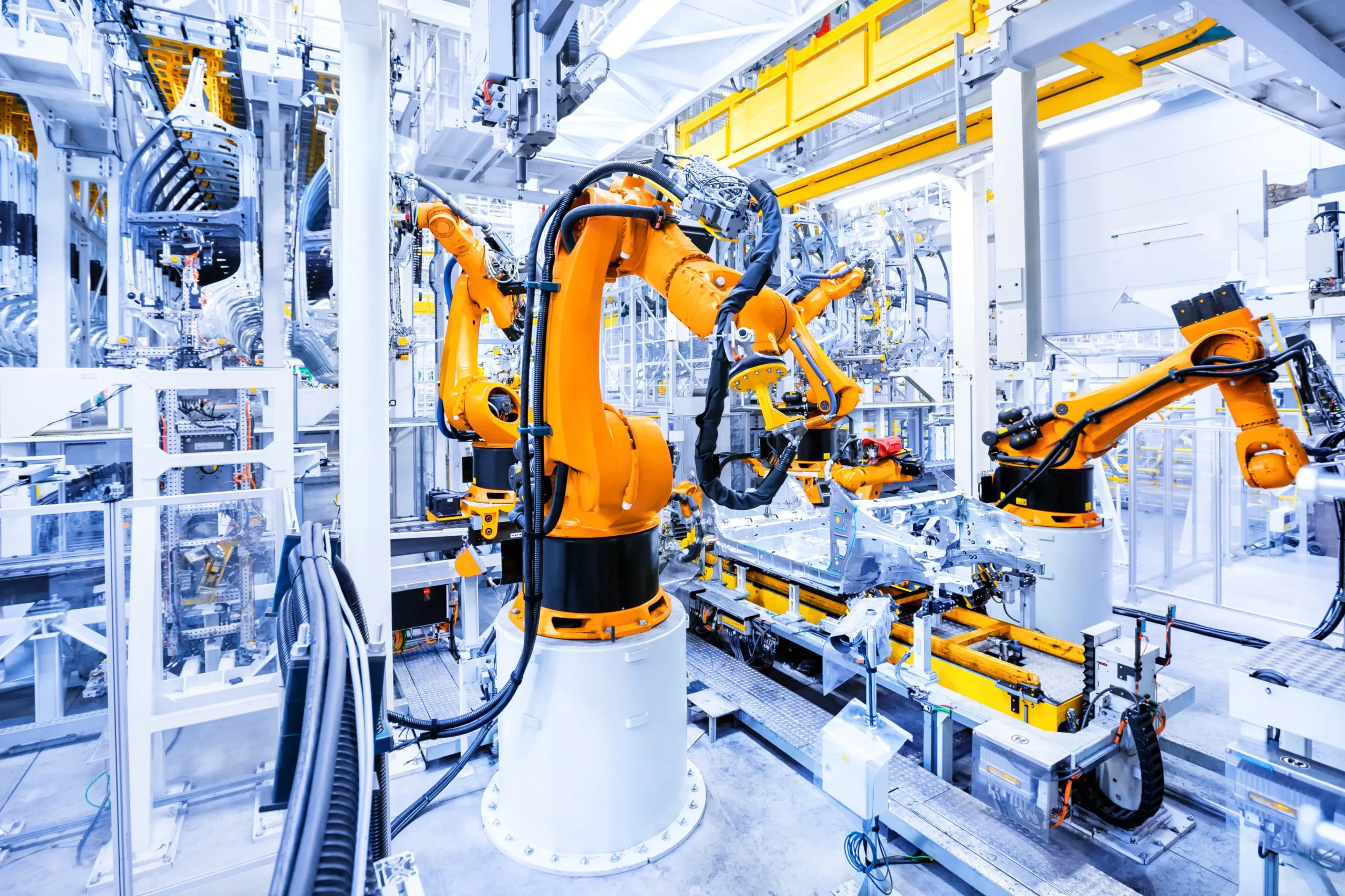

As a manufacturer for the Aerospace and Defence industries, you need to balance your processes with strict regulations for product compliance and export controls. It all raises the need for optimal workflows and an IT platform of integrated systems.

For Aerospace & Defence manufacturers to stay competitive, they must be able to implement solutions that interconnect information and processes – not only across the internal enterprise and departments – but external partners and suppliers as well. When CAD, PLM and ERP are not fully integrated and operate as silos, corporate-wide information sharing and collaboration becomes nearly impossible. Consequentially, Aerospace & Defence manufacturers suffer delays, miss cost targets, slow change cycles and orders that end up not fulfilling customer requirements. These increased industry demands means that manufacturing companies are facing several critical challenges that are tightly connected to a deep integration between Engineering and Manufacturing.

With Bluestar PLM, you can have an enterprise that meets the challenge by bringing your entire product record into on single source of truth in real-time, anytime and across all your teams.

Challenges of non-embedded PLM and ERP systems

Benefits for Aerospace and Defense companies

Enforce procedural and regulative compliance

Best-practice workflows are reused as templates in repetitive business processes ensuring compliance with official procedures.

Strict regulations in industries like aerospace and defence are managed in Bluestar PLM with seamless reporting and calculations that ensure your products does not exceed thresholds for substances of high concern.

Better quality products

Allows you to standardize your business processes to easily repeat them over and over. This makes it much easier to optimize your predefined product configurations, for optimal end product.

Reduced costs

With largely automated business processes and product standardizations, optimized processes are obviously cheaper than developing a new process or product that is only ever used once.

Shorter time to market

With Bluestar PLM fully embedded in Dynmaics 365 F&SCM, departments and sites can extend their work and collaborate in a single digital environment, so sales, engineering, procurement, and manufacturing processes can run parallel to each other, eliminating wait times.

More innovation

The time you save with standardized business processes and configured products can be used to optimize existing processes and new product developments.

Fewer mistakes

Repetition of processes means more routine in execution. Potential errors are prevented and production is streamlined.

Design automation

Automatically generate 3D CAD-models and detailed drawings based on product variants and configurations. As a result, you will save hundreds of hours otherwise spent on design processes.

Product visibility

Bluestar PLM enables seamlessness between sales, engineering, and manufacturing. What engineers has defined as a configured product, will immediately be shown in real time, so all departments and locations will have the latest and accurate information to work with.

What have our customers accomplished?

Automated Bakery Equipment Solutions

Achieved 150% revenue growth, due to PLM and ERP implementation. Errors were reduced, and quality management boosted product reliability and customer satisfaction. Streamlined processes increased productivity across all functions…