Engineering Change Management (ECM)

Bluestar PLM offers a scalable module-based PLM solution for Microsoft Dynamics 365 Finance & Supply Chain Management, delivering different levels of integration with CAD, PLM and ERP, fitting your unique business needs. Start simple by CAD/PDM + ERP Connectors, explore a single business system by having CAD + PLM + ERP with Bluestar PLM, or move your business towards enterprise product configuration by choosing the Product Configuration Module.

Manufacturers are repeatedly faced with input from customers, suppliers, and other stakeholders which, directly or indirectly, advocates for product modifications. This input triggers internal engineering change control processes that are complex in nature, involving many objects, tasks, and people who may be scattered across several departments and locations. Successfully executing these engineering changes is a matter of absorbing this input into an engineering change management process which manages the objects affected by the change, and routes change-related information and tasks to the agents responsible for the affected objects.

With all your product data in one system, which could be an engineering change management software, you will have complete transparency in your change management engineering procedures. This software will fully enable you to understand the design, manufacturing, and supply chain impact of engineering changes before they are implemented and enforce best-practice and workflow-driven end-to-end business processes. This facilitates better business decisions and ensures that drawings and related documentation always reflect the latest changes. The employment of engineering change management software effectively improves the efficiency and accuracy of the engineering change control process, thereby enhancing overall product development and lifecycle management.

Bluestar Engineering Change Management helps you:

- Determine change impact: Understand the impact of engineering changes on the supply chain across product designs, transactions, routes and more before executing the ECO.

- Execute and trace engineering changes: ECO’s and all related data, processes and people are traced with automated workflows, from initial request to implementation. Improves efficiency and reduces errors.

- Audit trail: Gives you complete historic visibility in D365/AX on ECO’s, so you can easily audit and know what was changed, when, why and by whom.

- Integrate with D365 Engineering Change Management: Bluestar ECM works in parallel with D365 ECM, ensuring that the whole change is covered within a single flow in one system, but also improves the traceability and manageability of multi-revision product data without losing any of the Bluestar PLM functionality.

Transparent and traceable engineering change processes to prevent errors.

See how it works

Understand the supply chain impact of engineering changes before they are implemented

- Promote engineering changes through the entire change cycle across CAD, PLM and ERP, all the way from request through the actual implementation of the change in D365/AX.

- CAD + PLM + ERP in one system provides complete transparency in the cost and logistic feasibility of engineering changes and ensures that affected products and associated documents are revision controlled and always up-to-date during the entire change process.

Enforce workflow driven change processes to improve time-to-market.

Key Features of Engineering Change Management

End-To-End Change Management

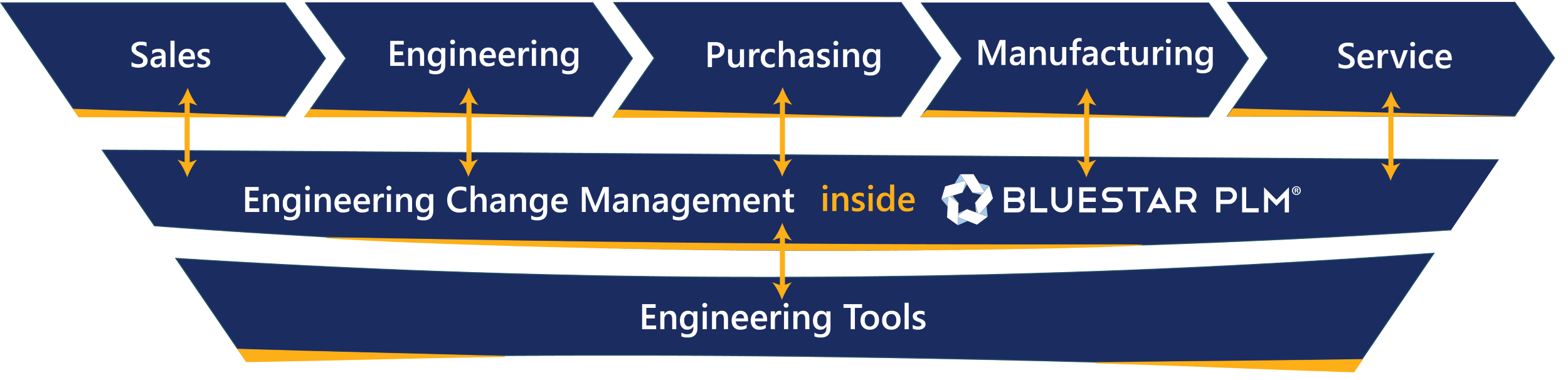

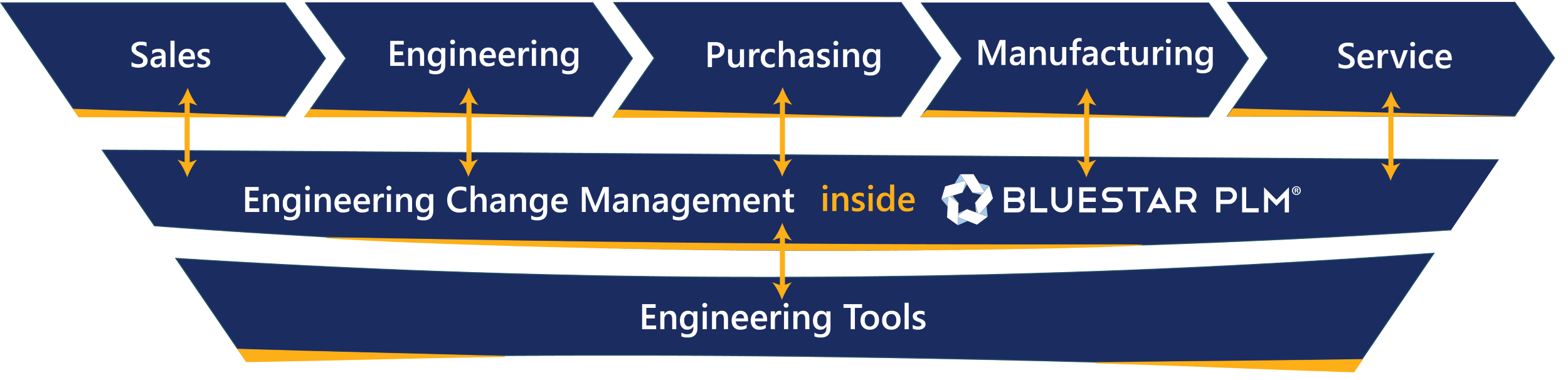

Provides an integrated platform for creating, planning and implementing product changes while taking all dependencies in Sales, Engineering, Purchasing, Manufacturing, and Service into account.

Workflow Automation

Drives ECO processes spanning engineering and operations with cross-functional workflow automation. A graphical drag and drop design engine allows for the easy creation of best-practice workflow templates.

Revision Trail & Comparison

Stores a complete revision history of D365/AX items, BOMs and the associated drawings and technical documentation. Enables the comparison of indented BOM revisions.

Affected Designs Analysis

Generates a list of how other product designs are affected by a product change.

“What-If” Scenarios

Enables ECO cost and feasibility calculations to help make better change decisions.

Mass Replace

Easily replace or delete a part wherever it is used on other BOMs.

Change Impact Analysis

Analyses the impact a product change has on routes and work-in-progress (sales orders, production orders, purchase orders, inventories, etc.).

Release Control

Advanced control of when and to which Dynamics 365/AX Companies revisions are released.

Integration with Dynamics 365 ECM

The interconnectivity between Bluestar PLM – and D365 ECM allows creating change requests in D365, completing the engineering changes in Bluestar PLM, then finalizing the change with the manufacturing changes in the D365. This not only ensures that the whole change is covered within a single flow, but also improves the traceability and manageability of multi-revision product data without losing any of the known Bluestar PLM functionality.

Your Benefits with Engineering Change Management

Know the cost and feasibility of engineering changes

An overview of the downstream impact enables you to take more informed and cost-beneficial decisions related to engineering change orders. Save time by not having to identify the impact of change manually.

Shorten change cycles

Ensure the timely phase-in of new revisions in D365/AX with improved responsiveness towards input from customers and colleagues.

Enforce best practice change procedures

Your entire organization operating in a shared CAD + PLM + ERP environment will abide by formal change procedures for increased quality and consistency.

Increased engineering productivity

Eliminate redundant administrative processes that accompanies engineering changes when all product data is connected in a single system – D365/AX.

Reduce errors in the change process

Easier manage and monitor engineering changes with an overview of the complete change history and latest updates, so production will always have access to the latest revisions for reducing costly errors in production.

Increased collaboration and coordination across the organization

With both ERP and PLM change-related data shared across engineering and operations, you will be able to coordinate multiple changes simultaneously with greater precision.

Spend less time on briefing stakeholders with complete data transparency

With both ERP and PLM change-related data shared across engineering and operations, people will be informed and prepared to handle change requests so you can spend less time getting stakeholders up to speed during meetings.

CAD, PDM and PLM supported by Bluestar PLM:

SOLIDWORKS PDM

AUTODESK VAULT

INVENTOR

SOLID EDGE

SOLIDWORKS

EPLAN

ORCAD

PADS

ALTIUM

DRAFTSIGHT

CATIA

CREO

TEAMCENTER

WINDCHILL

SIEMENS NX

AUTOCAD

AUTOCAD PLANT

AUTOCAD ELECTRICAL

BIM

REVIT

And more…

Manage your 2D/3D files, PDM and CAD systems with Bluestar PLM

More Key Features inside the Bluestar Engineering Change Management suite

Engineering

Analytical tool

Integration and flow

Documentation

Poul Bak Pedersen

Sales Director EMEA

pbp@bluestarplm.com