Product Compliance

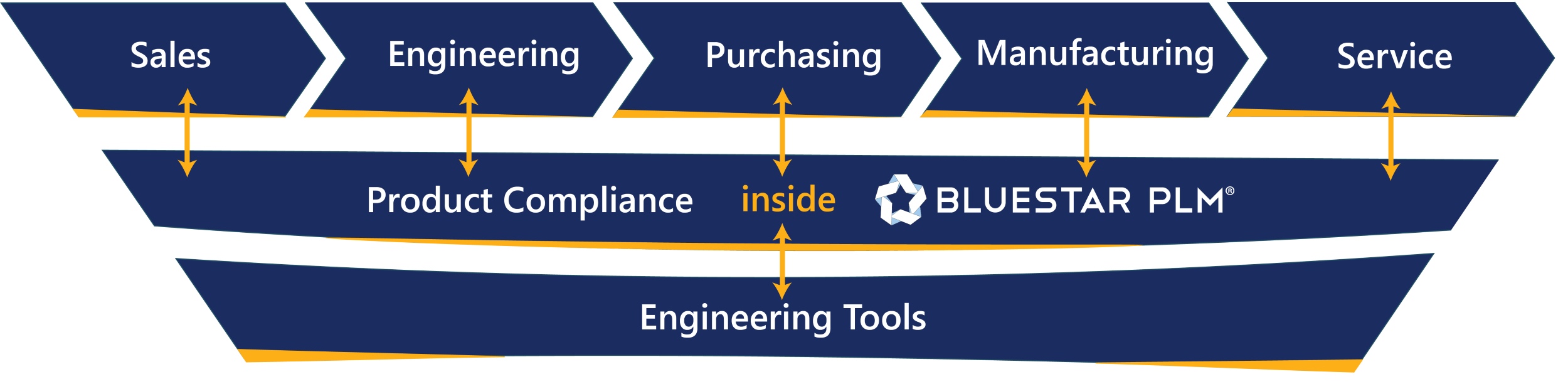

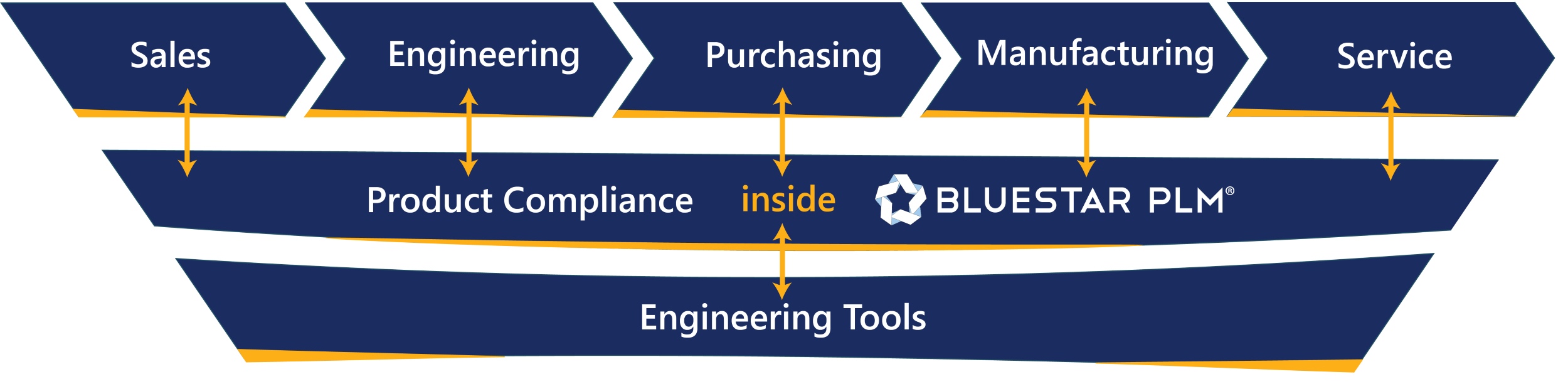

Bluestar PLM offers a scalable module-based PLM solution for Microsoft Dynamics 365 Finance & Supply Chain Management, delivering different levels of integration with CAD, PLM and ERP, fitting your unique business needs. Start simple by CAD/PDM + ERP Connectors, explore a single business system by having CAD + PLM + ERP with Bluestar PLM, or move your business towards enterprise product configuration by choosing the Product Configuration Module.

As a manufacture producing electronic components, you are required to keep track of all the materials used in your products. This is a comprehensive but necessary task, as you are obliged to do so by international regulations, which requires you to share your compliance data with suppliers, customers, and regulatory authorities. This is challenging however, as chemical reports and specifications are traditionally scattered across multiple solutions and databases. Without proper visibility in your compliance data, you will not be able to calculate and provide this information. Consequentially, you will face non-compliance, resulting in not only costly fines but lost market share and discreditation.

Bluestar PLM helps you to ensure your products stay compliant with international substance regulations based on RoHS, REACH and other global directives.

Bluestar Product Compliance helps you:

- Collect all material information inside D365/AX: Access the BOM and all the revision-controlled chemical information for your parts, which you need to document compliance. This includes substance lists, chemical regulations and material declarations.

- Component Library integration (e.g., Silicon Expert): Seamlessly import up-to-date component information on End-of-life (EOL) stage, substances, footprints, lifecycle statuses, parametric data, and other manufacturing data to reduce time-consuming manual tasks otherwise needed to acquire and track reliable data on electronic components.

- Calculate compliance: Automatically calculate if your products substance composures comply with regulations like REACH and RoHS to ensure compliance.

- Export Full Material Disclosures (FMD): Material reports can easily be shared with suppliers and stakeholders, so everyone in your supply chain will know that your products are not hazardous and stay within compliant thresholds.

Collect and calculate material data inside D365/AX to comply with international regulations.

Learn why Bel Group chose Bluestar PLM and Product Compliance Module

Stay compliant with full product material disclosure inside D365/AX:

- Uphold obligations to notify regulatory authorities like ECHA in the EU or EPA in the US with full material disclosure collected and calculated so you stay compliant.

- Comply with customized standards from your customers to ensure that you comply with both governmental regulations and requirements from your supply chain as well.

Seamlessly share full material disclosure reports and substance calculations across the supply chain.

Key Features of Product Compliance Module

Exemption management

Assign approved exemptions to your items, so you will know when allowances permit you to make products that otherwise go against regulations.

Compliance calculation

Bluestar Compliance is capable of automatically calculating the mass and concentration of each substance against the thresholds of specifications. When calculations are easy to perform like this, you reduce the risk of making non-compliant products.

Importing/exporting full material disclosures

Import chemical data and full material disclosure reports into Bluestar Compliance or export them to your suppliers and customers, to ensure all your partners and stakeholders are able to document compliance as they are obliged to. The data is imported automatically in a controlled manner, eliminating the need for manually mapping the data.

Alternative substance names

Any substance can easily be found in the Bluestar system, as you can search for it by both its trivial and chemical name; i.e. lead = Pb.

Manage manufacturing items

Every manufacturing item gives you a full material disclosure with all chemical data associated with that item. Centralizes all your compliance data in one system for everyone to access.

Revision control

Revise and manage all your manufacturing items and associated data, so you will always know which is the latest version. With revisions, you can also backtrack to find out how and when errors or mistakes happened during engineering change processes.

Where-used analyses

Reveals all the manufacturing items, exemptions and specifications containing any particular substance. Makes you aware of which products and substances are affected by regulated specifications across your entire product line.

Component Library integration

Seamlessly import and map reliable chemical data on manufacturing items, substances, and specifications from a Component Library (e.g., Silicon Expert), which you need to follow as a compliance obligation. Saves you the effort of doing otherwise error-prone work when manually transferring data from one system to another.

Phase out products End-of-life – EOL

Define and manage the last stages of the electrical component’s life, and determine when to stop marketing, selling or reworking for sustaining the product.

Your Benefits with Product Compliance Module

Centralize compliance data in a single solution

Provide everyone in your organization easy access to compliance information, in a single solution with a centralized repository for data on product substances and the chemical specifications stated by regulations.

Gain access to crucial chemical data from a third-party data provider

By easily importing reliant data from a Component Library (e.g., Silicon Expert), you will always have access to substance lists and chemical specifications for your products.

Ensure all your stakeholders stay compliant

Importing and exporting full material disclosures (FMD’s) allows you to share knowledge with everyone in your supply chain who depends on it to stay compliant.

Enhance compliance through automation

Automatically synchronize with the chemical specifications and calculate your product compliance, instead of having to do this manually, resulting in costly errors, rework or products rejected by the market.

CAD, PDM and PLM supported by Bluestar PLM

SOLIDWORKS PDM

AUTODESK VAULT

INVENTOR

SOLID EDGE

SOLIDWORKS

EPLAN

ORCAD

PADS

ALTIUM

DRAFTSIGHT

CATIA

CREO

TEAMCENTER

WINDCHILL

SIEMENS NX

AUTOCAD

AUTOCAD PLANT

AUTOCAD ELECTRICAL

BIM

REVIT

And more…

Manage your 2D/3D files, PDM and CAD systems with Bluestar PLM

Poul Bak Pedersen

Sales Director EMEA

pbp@bluestarplm.com