Electronics CAD

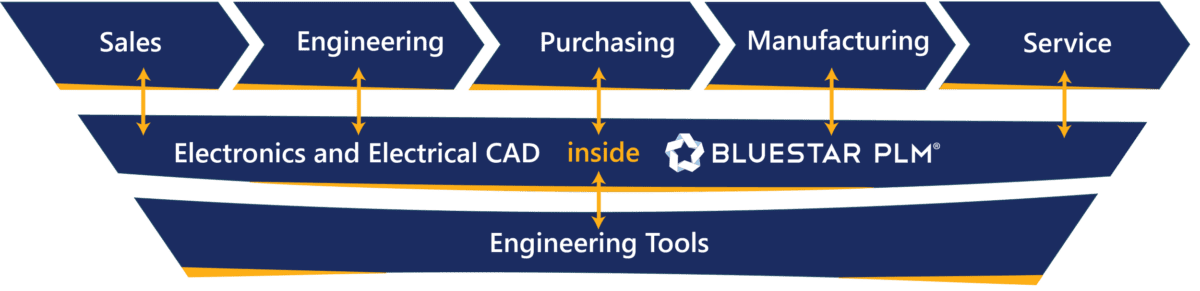

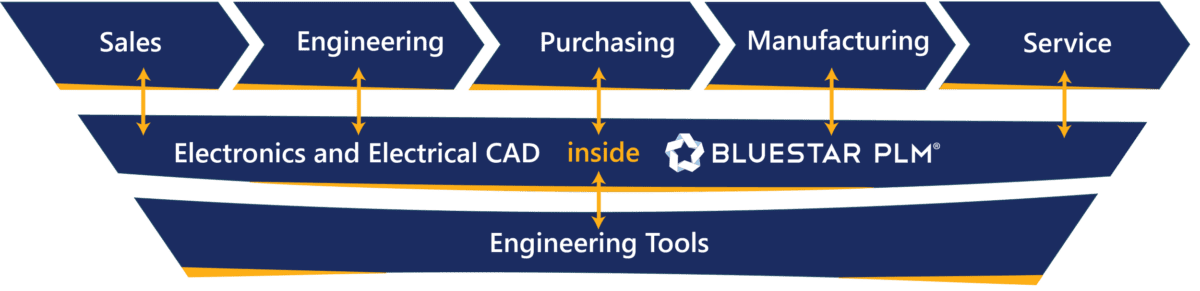

Bluestar PLM offers a scalable module-based PLM solution for Microsoft Dynamics 365 Finance & Supply Chain Management, delivering different levels of integration with CAD, PLM and ERP, fitting your unique business needs. Start simple by CAD/PDM + ERP Connectors, explore a single business system by having CAD + PLM + ERP with Bluestar PLM, or move your business towards enterprise product configuration by choosing the Product Configuration Module.

Failure to properly manage obsolescence issues can have serious consequences for manufacturers of electronic products, since these issues can threaten the integrity of end products and bringing manufacturing to a halt. Also, redesigning products due to component obsolescence is financially devastating and time-consuming when production and delivery are delayed.

As a manufacturer of electronic products, you need a component management system that provides real-time updates on multiple component sources, so you will acquire only the most cost-beneficial and high-quality parts for your products. Connect your preferred ECAD solutions with Bluestar PLM, allowing design-engineers in CAD to seamlessly exchange product data and related documentation with the downstream supply chain in Dynamics 365/AX.

Embedding your ECAD solution with Bluestar PLM helps you:

- Synchronize component libraries between D365/AX and ECAD: Lifecycle status and part information on electrical components are stored in Bluestar PLM and D365/AX – and synchronized with the component database in your local ECAD system – no need to leave your CAD environment.

- Access BOM-centric PLM/ERP data: All electronic, mechanical and software components and related data are collected in a single revision-controlled hierarchical BOM structure stored in D365/AX.

- Multi-CAD collaboration: Design teams can easily exchange the latest product designs by leveraging multi-discipline design across mechanical and electronics in one single CAD system.

- Comply with international material regulations: Store your material declarations for your products in D365/AX and calculates substance composures so you do not exceed limits on hazardous materials, stated by REACH, RoHs and other regulations from the global market.

- Silicon Expert integration: Seamlessly import the latest data on EOL and material information for parts, from the Silicon Expert database to stay updated with the ever-evolving market of electronic products.

Synchronize component data between ECAD and D365/AX to streamline PCB designing.

Supported CAD systems

Bluestar PLM is fully integrated with multiple mainstream ECAD systems for the design of electronic products:

ORCAD

ALTIUM

PADS

Seamlessly synchronize your ECAD solution with D365/AX

- CAD users can easily share electronic PCB designs with other design disciplines inside a single CAD environment to communicate design intent and catch constraints early in product development.

- Achieve full material disclosure for all your electronic products inside D365/AX and calculate material composures against regulations, to ensure you do not release prohibited products to market.

Connect Engineering and Operations by integrating CAD with PLM/ERP inside D365/AX.

Key Features of Electronics and Electrical CAD Module

Integration with Third-Party data providers

An integration with third-part data providers, like Silicon Expert, grants you instant access to the latest information on parts at risk, an in-depth look into electronic component lifecycle statuses, and environmental compliance data.

Centralized and controlled product information

A hierarchical product structure is automatically created in D365/AX which captures not only the BOM, but also all associated product documentation. All product documentation ever created in the lifecycle of a product is conveniently accessible in a single tab in D365/AX.

Multi-CAD collaboration

STEP–file conversion allows design teams across disciplines to easily exchange the latest product changes in D365/AX and leverage designs across MCAD/ECAD in a single CAD system.

Approved Manufacturer List (AML)

From the AML list, vendors can trace and cross-reference information on component risk analysis, EOL, last time buy, and much more from different providers.

Manage product lifecycle statuses

With real-time updates from Silicon Expert on EOL dates and component expirations, you can initiate change requests to terminate, exempt or renew components to ensure you only produce compliant products.

Compliance management

Achieve full material disclosure for all your products and automatically calculate material composures so your products don’t exceed regulated substance levels.

Structured workflows and change processes

In order to meet product delivery and stay within budgets, Bluestar PLM supports best-practice end-to-end workflows and change management which lets PCB designers define and adjust workflows to their unique processes.

Enterprise-wide component management

Bluestar PLM automatically identifies any new or updated parts that needs to be synchronized. This lets product manufacturers reduce part duplication and prevent use of obsolete or unapproved parts. The component library is synchronized between ECAD and D365/AX so users do not have to switch between applications to search for information.

Your Benefits with Electronics CAD Module

Trace work in progres and reduce errors

Track the latest product changes – in real-time – and who made them with audit trails for complete visibility and traceability. In this way, all changes that come in are immediately addressed to reduce errors and improve efficiency.

Seamlessly share parts libraries between ECAD and D365/AX

ECAD and D365/AX seamlessly exchange component data in real-time so you have reliant data directly in your design environment. Part information and lifecycle status as well as lead time information is acquired prior to releasing the BOM for approval. This vastly improves time-to-market and mitigates the number of errors related to component stock issues or obsolescence.

Uphold your product compliance obligations

Identify non-compliant products before costly mistakes are made at the point the product goes into manufacturing and release. Avoid products being taken off-market, paying huge fines, and suffering severe credibility loss of your brand.

Integrate global business processes

End-to-end issues are tracked and coordinated, and change impact analysis lets you understand the impact of design decisions to arrive at a far more optimal and cost-beneficial design.

Trace your suppliers to get the most cost-beneficial parts

Bluestar PLM collects all the essential component data from multiple of your suppliers in one place, making it easy for you see who can provide you the parts you need at the best price, quality and lowest risk.

Faster product development

Product data (CAD, PLM and ERP) centralized in a single solution promotes greater reuse and saves you time otherwise wasted on searching for information when all product related data is collected in a single BOM – in a single system.

Trace the latest data on consistently evolving electronic components

A tight integration with the Silicon Expert database ensures you are always synchronized with the latest life-cycle statuses and material specifications for electronic components so you can stay compliant and not produce expired or banned parts.

Improve collaboration between Engineering and Manufacturing teams

Integrate multiple formats of MCAD and ECAD design data into one place. Design intent and incremental engineering changes on PCBs and mechanical enclosures are shared immediately between design teams, lowering the risk of discovering constraints and errors late in development. Grants you a faster and more efficient development process.

More Key Features

Products

Products

Poul Bak Pedersen

Sales Director EMEA

pbp@bluestarplm.com