Engineering Quality Management

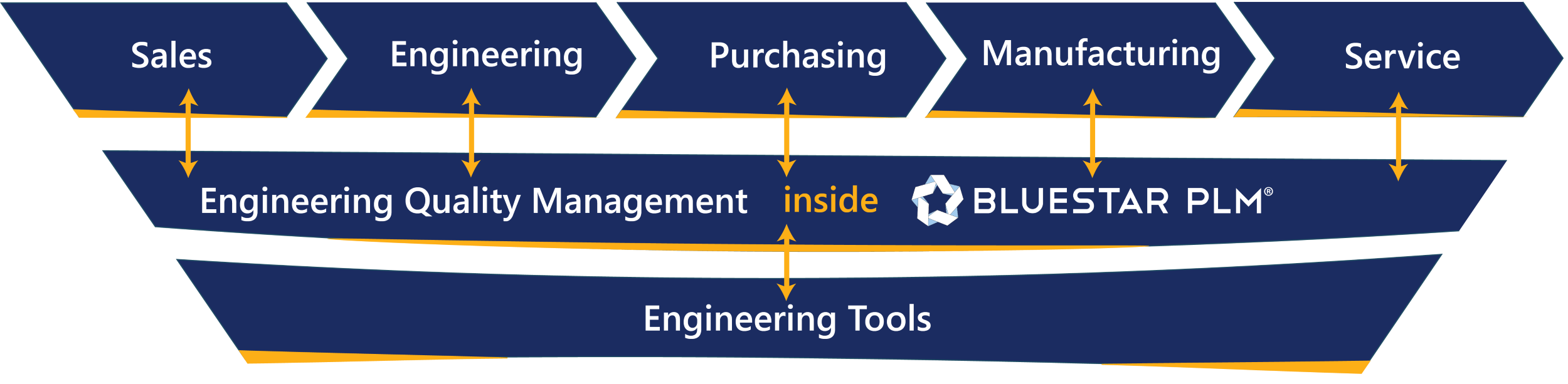

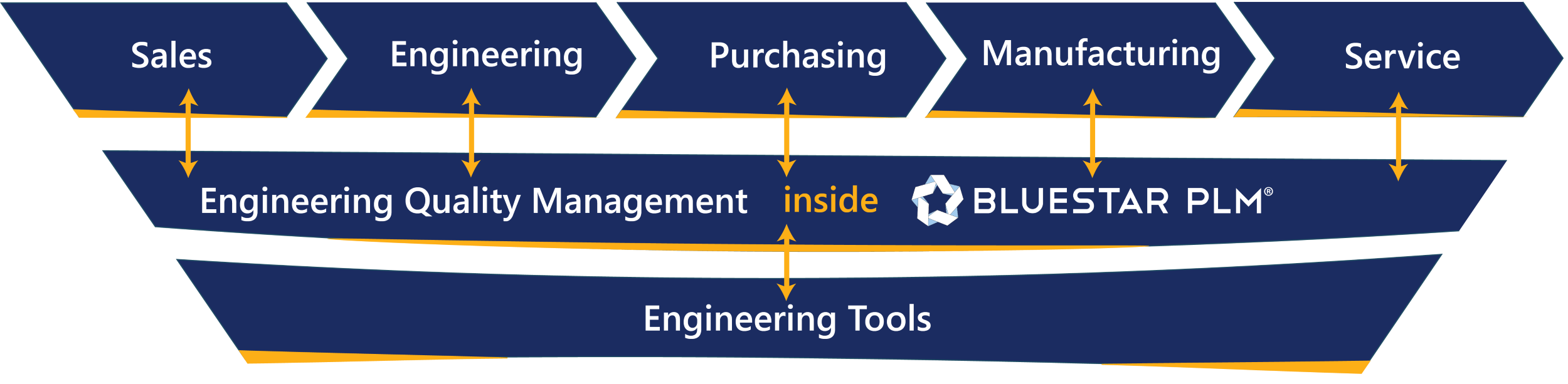

Bluestar PLM offers a scalable module-based PLM solution for Microsoft Dynamics 365/AX, delivering different levels of integration with CAD, PLM and ERP, fitting your unique business needs. Start simple by CAD/PDM + ERP Connectors, explore a single business system by having CAD + PLM + ERP with Bluestar PLM, or move your business towards enterprise product configuration by choosing the Product Configuration Module.

Failure to properly manage specific quality related requirements can be truly devastating for any manufacturer. Not registering non-conformances resulting from customer complaints, corrective actions not being taken and documented, or missing definitions of tolerances, inspections and tests can all be highly expensive and lead to lack of approval from the authorities.

Offering quality management functionality on top of the existing D365/AX quality module, Bluestar Engineering Quality Management enables you to easily build your own QMS applications to accommodate your specific quality related requirements.

Bluestar Engineering Quality Management helps you:

- Improve quality management and assurance: Manages quality-related processes for handling non-conformances reported through internal audits and customers, or the extended enterprise and suppliers.

- Identify and instantly respond with corrective and preventive action: To non-conformances for optimum customer service, maintenance and product quality.

- Manage engineering changes: Document and trace product changes across the supply chain, from request to implementation in D365/AX

- Stay in compliance: Comply with the most stringent quality standards such as Automotive (TS) and the acknowledged ISO standards 9000.

Comply with organizational and customer requirements in D365/AX

Corrective actions are conducted and documented based on non-conformances and supplier claims.

- Version Management: Keeping track of who created what documents, reviewed, changed and updated them, to ensure optimum product quality and mitigating errors.

- Conformancy: Avoid non-conformances resulting in decreased profits and market share.

- Reduce errors: Implementing best practices like 8D that rigorously track data on corrective and preventive actions, to continuously meet customer requirements.

Enhance existing D365/AX qaulity management capabilities to meet specified quality requirements.

Key Features of Engineering Quality Management

Configurable Quality Management Platform

Provides the platform for creating QMS applications to meet your specific requirements without any programming or Dynamics AX development skills required. QMS applications are born with workflow, revision control, document management and more.

Redlining

The BOM redlining functionality provides a quick overview of how a revision of a BOM is different from the previous revision. The 3D redlining enables the graphical comparison of BOM revisions in 3D or dimensional comparison of single part revisions.

Quality Control Specifications & Registrations

Ensures that quality control factors such as tolerances, inspections and tests, can be defined by engineering and automatically applied at the appropriate route operations in D365 / AX. Data and files captured during measurements, inspections and tests are stored against the items in D365/AX.

Engineering Change & Revision Control

Manage and document your product changes from initial request through actual implementation in a single controlled environment.

Non-Conformance

Provides an integrated platform for registering non-conformances resulting from customer complaints, incoming goods, and ensuring the relevant corrective actions are conducted and documented.

Corrective & Preventive Action

Non-conformances trigger workflows to ensure that the appropriate corrective actions are taken and documented. Preventive actions are likewise registered and controlled.

Document Control

Get your documents under control using status control, approvals and change management capabilities.

Explore our other modules

Poul Bak Pedersen

Sales Director EMEA

pbp@bluestarplm.com