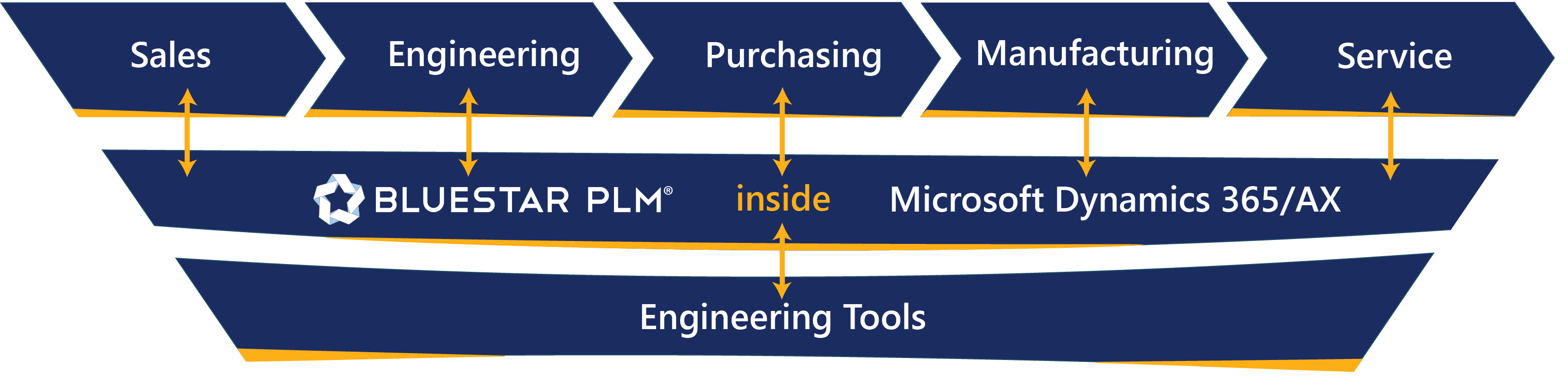

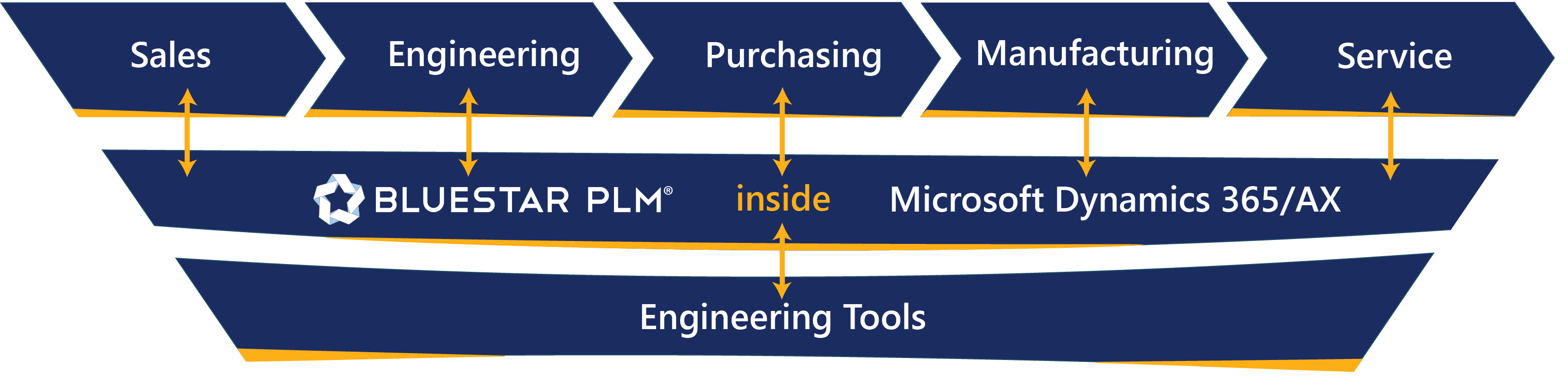

PLM system embedded in Microsoft Dynamics 365 F&SCM

Bluestar PLM offers a scalable module-based PLM system for Microsoft Dynamics 365/AX, delivering different levels of integration with CAD, PLM and ERP, fitting your unique business needs. Start simple by CAD/PDM + ERP Connectors, explore a single business system by having CAD + PLM + ERP with Bluestar PLM, or move your business towards enterprise product configuration by choosing the Product Configuration Module.

Bluestar PLM gives you:

- CAD, PLM and ERP data shared in D365/AX: Manage your items, BOMs and 2D/3D-models in one solution.

- One source of product truth: Complete data transparency for all departments and locations.

- Engineering Change Management: Transparent ECM that reveals change impact on designs and the supply chain before it is implemented.

- Multi-site collaboration: Seamless exchange of real-time data in the cloud.

- Workflow driven process automation: End-to-end engineering and operations processes executed in one system.

CAD + PLM + ERP: Digitize your Product Data Highway

See how it works in two minutes

Streamlined and transparent data across Engineering, Operations and Manufacturing

- Bluestar PLM system consolidates product data from CAD, PLM and ERP applications in a single revision-controlled data repository – D365/AX.

- Users in manufacturing always have access to the latest designs and related documentation mitigating costly mistakes during production.

- Engineering teams can instantly access centralized transactions and manufacturing data from ERP and incorporate it into product design.

Work faster, smarter and global with Bluestar PLM.

Key Features of Bluestar PLM system

Embedded in Dynamics 365/AX

Developed on and for the Microsoft Dynamics 365/AX ERP platform for optimum integration between engineering and manufacturing, and lower TCO.

Product Data Centralization

Consolidates data and documents from CAD, Office, PLM and ERP environments in a single, corporate-wide data repository.

Product Classification

Hierarchical product classifications and classification-specific attributes enable consistently exact part descriptions to ensure optimal data reuse.

Engineering Change Management

Manages the change management process from initial request through impact analysis and implementation in the production system.

Business Process Automation

Drives business processes from start to finish across departments and locations using an intuitive graphical workflow engine.

Multi-Site Engineering Collaboration

Enables collaboration between geographically dispersed engineering teams through intelligent file replication.

3D CAD File Management

Automates the exchange of data and files between Dynamics 365/AX and a range of supported CAD systems.

Product Structure Management

Visually manage multi-level bills of materials, associated drawings and documentation in a single indented product structure view. Easily create new product structures using powerful drag & drop design.

Revision Control

Tracks revisions of Dynamics 365/AX items and their related drawings, 3D models, routes and technical documentation for optimum traceability.

Document Management

Ensures that revision-controlled documents are maintained in relation to specific revisions of 365/AX items.

Additional Features

Product

Integration

System

Sharing

Your Benefits with Bluestar PLM system

A single source of product truth

Reliable product data available at the point-of-use for the entire enterprise ensures greater data integrity to make informed business decisions.

One platform for engineering and manufacturing

A seamless flow of real-time information between CAD, PLM and ERP embedded in one system, relieves manual data entry saving you time and money.

Enterprise-wide collaboration

Collaborate efficiently across destributed multi-discipline engineering and manufacturing teams, as well as sub-suppliers and the extended enterprise.

Optimal data reuse

By streamlining the reuse of existing product data and files, you will achieve a faster time-to-market, save time and improve product quality.

One user interface and a single system to maintain

Leverages the familiar user interface of Microsoft Dynamics 365/AX, with a single system to maintain instead of separate PLM and ERP systems. Having a single interface facilitates user adoption.

Drive business processes across engineering and manufacturing

A seamless flow in end-to-end business processes allow engineering and manufacturing to work in parallel for more efficiency and shorter lead times.

Module-based PLM system

Bluestar PLM is a scalable module-based solution, where you can choose the specific modules that fit your unique business requirements. Click below to learn more about the following modules:

- As-built Traceability

- Automatic CAD Designer

- BIM Integration

- Blueview 3D

- Business Process Management

- CPQ Integration

- Electronics and Electrical CAD

- Engineer-to-Order

- Engineering Change Management

- Engineering Quality Management

- Mechanical CAD

- Product Configuration

- Product Compliance

CAD, PDM and PLM supported by Bluestar PLM:

SOLIDWORKS PDM

AUTODESK VAULT

INVENTOR

SOLID EDGE

SOLIDWORKS

EPLAN

ORCAD

PADS

ALTIUM

DRAFTSIGHT

CATIA

CREO

TEAMCENTER

WINDCHILL

SIEMENS NX

AUTOCAD

AUTOCAD PLANT

AUTOCAD ELECTRICAL

BIM

REVIT

And more…

Manage your 2D/3D files, PDM and CAD systems with Bluestar PLM

Poul Bak Pedersen

Sales Director EMEA

pbp@bluestarplm.com