Mechanical CAD

Bluestar PLM offers a scalable module-based PLM solution for Microsoft Dynamics 365 Finance & Supply Chain Management, delivering different levels of integration with CAD, PLM and ERP, fitting your unique business needs. Start simple by CAD/PDM + ERP Connectors, explore a single business system by having CAD + PLM + ERP with Bluestar PLM, or move your business towards enterprise product configuration by choosing the Product Configuration Module.

Any manufacturer has faced errors caused by duplication or maintenance of data and documents, non-value-added work that took up too much time, searching for information, re-entering information, or poor or non-existent collaboration between engineering, purchasing, and manufacturing teams.

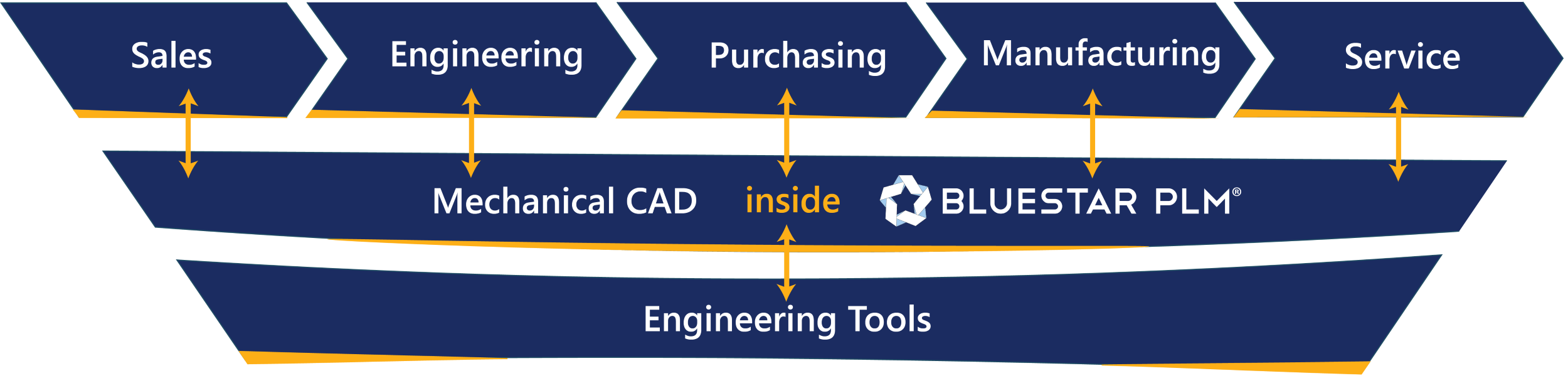

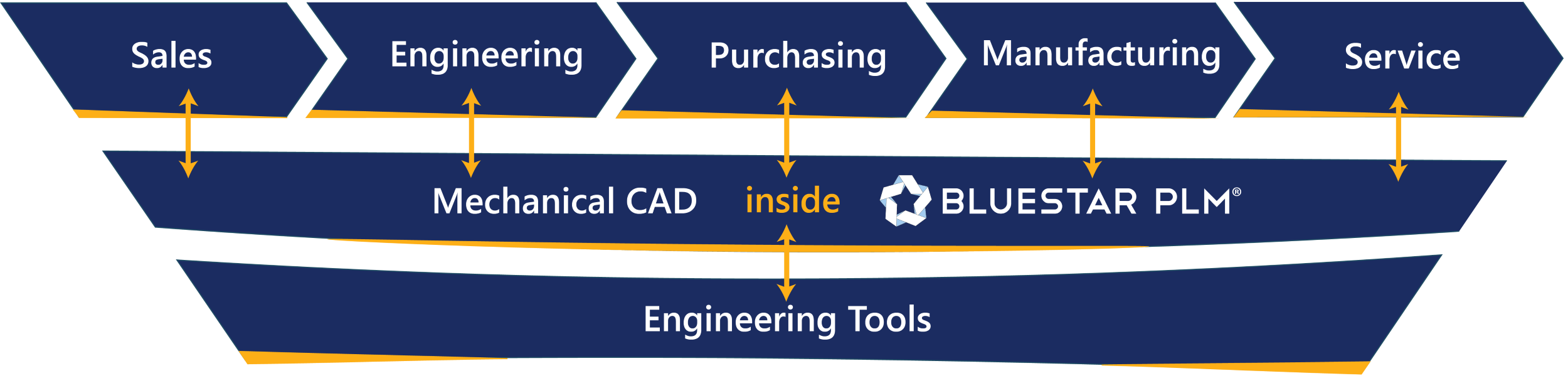

Connecting your MCAD system to Bluestar PLM fully embedded inside MS D365/AX ERP synchronizes CAD + PLM + ERP data in one system, providing the missing link between engineering and operations. With Bluestar PLM, design engineers rarely have to leave their CAD environment, empowering the design, configurability and reuse of products.

Integrating your MCAD solution with Bluestar PLM and D365/AX helps you:

- Exchange files between CAD, PLM and ERP: Automatic and seamless exchange of data on items, BOMs, drawings, manufacturing files, and STEP files across engineering and operations for more efficiency and less errors.

- Access item/BOM-centric PLM/ERP data: All electrical, electronics, mechanical, and software components as well as related data are stored in a single revision-controlled hierarchical BOM structure stored in D365/AX.

- Configurations and change management: Generate CAD models from configuration selections and update CAD models from BOM changes with a seamless exchange of product data between CAD, PLM and ERP.

- Re-use product data in CAD: Seamlessly re-use approved items, BOMs and configurations during product development to automate tedious engineering tasks of searching for and applying existing parts to new designs.

- Multi-CAD collaboration: Design teams can easily exchange the latest product designs by leveraging multi-discipline design across mechanical and electronics in one single CAD system.

- Integrate with your existing PDM/PLM tools: Bluestar PLM is capable of integrating and seamlessly sharing data with other external PDM and PLM systems, so you can continue working in your preferred business system, such as Solidworks PDM, Autodesk Vault and others.

Seamless exchange of BOMs, drawings and 3D files between CAD and ERP.

Supported CAD/PDM/PLM Systems

Integrate your existing CAD/PDM/PLM systems with Bluestar PLM. The entire end-to-end flow of product data across CAD, PDM/PLM and ERP in one system – D365/AX:

INVENTOR

CREO

SIEMENS TEAMCENTER

SOLIDWORKS

AUTOCAD

PTC WINDCHILL

SOLID EDGE

DRAFTSIGHT

CATIA

SOLIDWORKS PDM

SIEMENS NX

AUTODESK INVENTOR VAULT

Seamlessly synchronize your CAD solution with Bluestar PLM inside D365/AX

- CAD users can easily share design data and documents with downstream MS D365/AX users who depend on it for purchasing, manufacturing, etc.

- In return, CAD users are granted access to valuable transaction data from D365/AX such as prices, on-hand quantities, and lead times so that price awareness and other logistics considerations are easily incorporated into product designs.

Connect Engineering and Operations when CAD, PLM and ERP is embedded in D365/AX.

Key Features of Mechanical CAD Module

Exchanging files between CAD, PLM and ERP

Automatic and seamless exchange of real-time data on items, BOMs, drawings, manufacturing files and STEP files between CAD and ERP to improves collaboration between engineering, operations, sales, and service for more efficiency and less errors.

Product Configuration

Configure products and design product variants in CAD using a rule-based configuration engine, that lets CAD users select and modify product configurations while receiving live 3D feedback in CAD.

Utilize ERP data in CAD

On-demand access to real-time ERP data in CAD lets the design engineers efficiently incorporate and plan the design and release of products, according to data such as purchase orders, item lead-times, production lines, on-hand quantities, pricing and more.

Enhance collaboration between Engineering and Sales

A fast generation of sales documentation (3D models, sales and production drawings, DXF, STEP files and more) and less required involvement by Engineering in the quote process, leads to enhanced responsiveness to customer requests and freed up engineering resources.

Multi-CAD collaboration

STEP file conversion allows design teams across disciplines to easily exchange the latest product changes in D365/AX and leverage designs across MCAD/ECAD in a single CAD system.

Integrate with your existing PLM & PDM

Let engineering continue using their preferred PDM or PLM system – users of business systems like SolidWorks PDM, Autodesk Inventor Vault and more will be able to synchronize and streamline their data flow across CAD, PDM/PLM and Bluestar PLM embedded in D365/AX.

Centralized and controlled product information

A hierarchical product structure is automatically created in D365/AX which captures not only the BOM, but also all associated product documentation. All product documentation ever created in the lifecycle of a product is conveniently accessible in a single tab in MS D365/AX.

Reuse released product data in CAD

From CAD, easily search existing parts and products already released to PLM/ERP, based on classes and attribute filtering, as well as geometric similarities between parts. Saves engineers non-value adding time on searching for information scattered in spreadsheets and disconnected business systems.

Automatic CAD Designer

The Automatic CAD-designer application for CAD solutions makes product design faster and more efficient by tightly connecting CAD with PLM and ERP.

Empower and automate design processes such as searching for and mating geometrically related items, streamlining product development and speeding up time-to-market.

Design new products by re-using items and parts already existing in D365/AX. Your engineering teams will spend more time on innovation and product development and less time searching for items and re-creating and approving objects.

Continue to improve your business with CAD+PLM+ERP inside D365/AX.

More key features

Products

Products

Your Benefits with Mechanical CAD Module

Automate CAD design and product configuration tasks

Generate CAD models from rule-based configuration selections and automating taks of applying BOM changes to the model in CAD, rid design engineers of tedious tasks and make them more efficient.

Utilize ERP data in your CAD environment

On-demand access to ERP data in CAD lets design engineers easily incorporate transactions, on-hand quantities, pricing and more into product development for more efficiency and fewer errors.

Speed up time to market

Reliable and real-time product data flow freely and securely between engineering in CAD and the supply chain in ERP, with full historic traceability on all product changes up til the latest version, maximizing efficiency and reducing time-to-market.

Optimize engineering productivity

With CAD embedded in PLM and ERP, design engineers do not have to leave their CAD environment to spend tedious time on manually exchanging the latest product revisions with other teams. Spend time where it is most valuable: executing projects and perfecting designs.

Re-use product designs to empower engineering

Re-using released items and structures during product development mitigates time spent on re-creating and approving products from scratch.

Empower multi-discipline engineering

Remote engineering teams across domains can align electrical and mechanical designs in single CAD environment. This empower collaboration when design intent and constraints are shared in real-time thoughout the entire product development process.

Poul Bak Pedersen

Sales Director EMEA

pbp@bluestarplm.com